Subtotal: $13.56

DIY Underwater Video Camera

DIY Underwater Video Camera

This underwater camera is made by housing a small security camera inside a pressure tight container. This setup will work perfectly in clear water, but with increased water turbidity, lights will be necessary to improve performance. Construction details for the lights and housing are shown below.

This underwater camera is made by housing a small security camera inside a pressure tight container. This setup will work perfectly in clear water, but with increased water turbidity, lights will be necessary to improve performance. Construction details for the lights and housing are shown below.

This plumbing accessory form a local DIY store forms the main part of the housing. It was chosen for its compact size, and it allows both ends to be easily removed so the components remain accessible.

The two end caps are not fully closed. This allows a small perspex window to be added for the camera to see through. A perspex disc should be cut to fit neatly inside the cap with an o-ring either side. PTFE tape wrapped around the screw thread will ensure a tight fit when screwing on the caps.

The two end caps are not fully closed. This allows a small perspex window to be added for the camera to see through. A perspex disc should be cut to fit neatly inside the cap with an o-ring either side. PTFE tape wrapped around the screw thread will ensure a tight fit when screwing on the caps.

The cable is sealed in the middle of another perspex disc. This allows the ends to be unscrewed without twisting the cable. Layers of Polymorph and epoxy resin are built up either side of the disc, and around the cable to form a strong flexible seal.

The light source is an array of bright LED’s. The LED’s shown here are from surplus parts and are not the most effective light source for a camera. The best LEDs would be either white or infra red, as the camera will respond best to these. The LEDs and resistors were mounted on a plastic strip which is formed into a ring to fit over the end of the camera housing. They are sealed using Polymorph and epoxy resin.

The light source is an array of bright LED’s. The LED’s shown here are from surplus parts and are not the most effective light source for a camera. The best LEDs would be either white or infra red, as the camera will respond best to these. The LEDs and resistors were mounted on a plastic strip which is formed into a ring to fit over the end of the camera housing. They are sealed using Polymorph and epoxy resin.

The lights shown here are a combination of blue, ultra violet, white, and infra red LEDs. There are fifteen in total. It looks pretty cool, but a white or IR light would be better. The power for the LED’s was taken from the same 12V battery used for the camera so it was neccesary to reduce this power to a lower level for them. To do this a power pulse modulator was used with the frequency set high and the pulse width set very low. This served as a dimming module for the LEDs so the brightness could be finely contolled.

Check out he video captured with this camera in the Alsager Mere section.

Heatsink 50 x 50 x 12.8mm

Heatsink 50 x 50 x 12.8mm  This device utilises the cooling effect of

This device utilises the cooling effect of

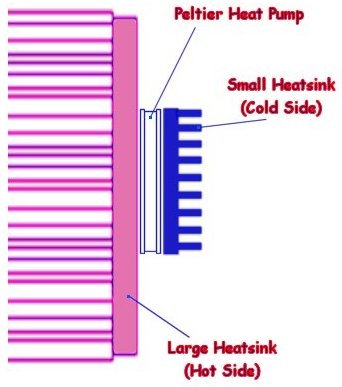

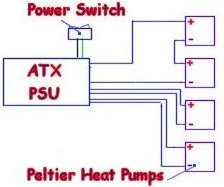

The device works by cooling the small blue heatsinks in the centre of the image. These are cooled to about 0 degrees Celsius (dependent on ambient temperature) which causes water to condense on the fins. When enough water has built up between the fins it will drip into the container below. The fan at the front simply keeps the air flowing over the cold fins, whereas the other fans are used to remove the heat from the heat pumps. In this image you can see a heat pump (peltier module) between the hot and cold heatsinks. Although this device is a useful demonstration of scientific principles, it is actually not incredibly practical or efficient.

The device works by cooling the small blue heatsinks in the centre of the image. These are cooled to about 0 degrees Celsius (dependent on ambient temperature) which causes water to condense on the fins. When enough water has built up between the fins it will drip into the container below. The fan at the front simply keeps the air flowing over the cold fins, whereas the other fans are used to remove the heat from the heat pumps. In this image you can see a heat pump (peltier module) between the hot and cold heatsinks. Although this device is a useful demonstration of scientific principles, it is actually not incredibly practical or efficient.  The aim of this project was to create a simple device capable of keeping components as cool as possible using common parts and materials. The device shown here is capable of maintaining a temperature of approximately -50° C.

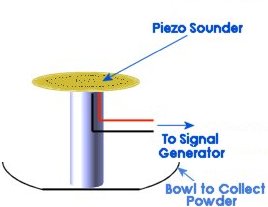

The aim of this project was to create a simple device capable of keeping components as cool as possible using common parts and materials. The device shown here is capable of maintaining a temperature of approximately -50° C. This diagram shows a flat Piezo sounder glued to the top of a small section of tubing for support. The connecting wires should be supported by attaching them to the tube. It is important that the wires are not tight as they may prevent the piezo sounder from oscillating fully. The wires can then be connected to an signal generator such as the

This diagram shows a flat Piezo sounder glued to the top of a small section of tubing for support. The connecting wires should be supported by attaching them to the tube. It is important that the wires are not tight as they may prevent the piezo sounder from oscillating fully. The wires can then be connected to an signal generator such as the

This is a battery powered motor for a small rowing boat. The motor used is from an electric wheelchair which ran from 24V. The motor has a built in reduction gearbox to provide a large torque to the wheels on the wheelchair. This gearing ratio was far to high for the propeller. The prop needs to turn much faster in order to generate the right amount of thrust to move the boat.

This is a battery powered motor for a small rowing boat. The motor used is from an electric wheelchair which ran from 24V. The motor has a built in reduction gearbox to provide a large torque to the wheels on the wheelchair. This gearing ratio was far to high for the propeller. The prop needs to turn much faster in order to generate the right amount of thrust to move the boat.

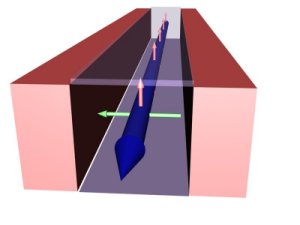

Based on the image on the left, it is possible to make a simple MHD thruster, just powerful enough to propel a toy boat.

Based on the image on the left, it is possible to make a simple MHD thruster, just powerful enough to propel a toy boat. Two opposing inner faces of a rectangular plastic tube are covered by metal strips. These are the main electrodes and should have a connection for a battery. Magnets are attached on the outside of the tube so that they are attracting each other, and are at 90° to the electrodes.

Two opposing inner faces of a rectangular plastic tube are covered by metal strips. These are the main electrodes and should have a connection for a battery. Magnets are attached on the outside of the tube so that they are attracting each other, and are at 90° to the electrodes. This setup shows the electrodes closer together than the magnets. The combination of magnets used in this device were not strong enough to move the electrified water with any decent force. At only 1.5V in salty water, large amounts of electrolysis occurs, but the water does generally flow in one direction.

This setup shows the electrodes closer together than the magnets. The combination of magnets used in this device were not strong enough to move the electrified water with any decent force. At only 1.5V in salty water, large amounts of electrolysis occurs, but the water does generally flow in one direction.

EHDT Construction Details

EHDT Construction Details

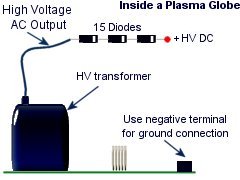

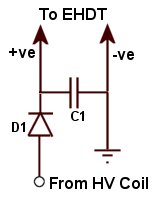

For a tiny Lifter the output of a plasma globe PSU and a

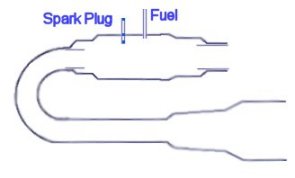

For a tiny Lifter the output of a plasma globe PSU and a  The valveless pulse jet engine or pulse detonation engine is the most simple type of jet and is therefore popular among hobbyists as a DIY project. it is often referred to as a ‘tuned pipe’ because its operation depends upon making the parts the right size and shape so that it fires, or resonates at the engines natural, fundamental frequency. This type of jet propulsion does not need any type of turbine, turbofan, or propeller, making it much less complex than a typical turbojet. In a turbojet the turbine or turbofan is used to compress the fuel/air mixture in the combustion chamber so that it is more efficient and powerful.

The valveless pulse jet engine or pulse detonation engine is the most simple type of jet and is therefore popular among hobbyists as a DIY project. it is often referred to as a ‘tuned pipe’ because its operation depends upon making the parts the right size and shape so that it fires, or resonates at the engines natural, fundamental frequency. This type of jet propulsion does not need any type of turbine, turbofan, or propeller, making it much less complex than a typical turbojet. In a turbojet the turbine or turbofan is used to compress the fuel/air mixture in the combustion chamber so that it is more efficient and powerful. These images show the basic ‘tuned pipe’ without the spark plug and gas supply. Tuning was achieved by altering the length and width of the parts used. This was quite simple as there are wide range of plumbing parts that will easily fit together.

These images show the basic ‘tuned pipe’ without the spark plug and gas supply. Tuning was achieved by altering the length and width of the parts used. This was quite simple as there are wide range of plumbing parts that will easily fit together. The spark plug its self was just a single wire inside a small glass fuse. This wire was connected to one capacitor terminal (live) and the body of the jet engine was connected to the other terminal (earth). The spark would jump from the tip of the wire to the inside of the combustion chamber to ignite the fuel mixture.

The spark plug its self was just a single wire inside a small glass fuse. This wire was connected to one capacitor terminal (live) and the body of the jet engine was connected to the other terminal (earth). The spark would jump from the tip of the wire to the inside of the combustion chamber to ignite the fuel mixture.