A DIY Mini Tesla Coil

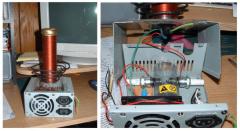

DC Powered with Plasma Output

The aim of this design was to get the highest voltage (or longest arcs) possible from a single self contained unit.

![]()

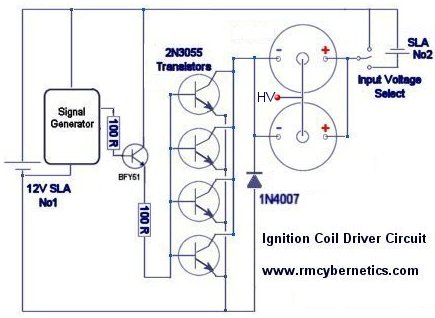

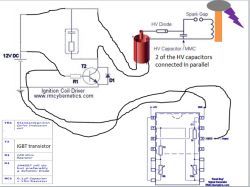

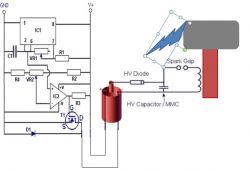

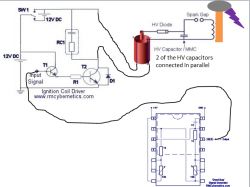

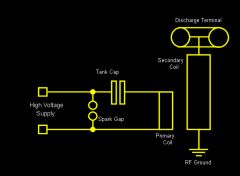

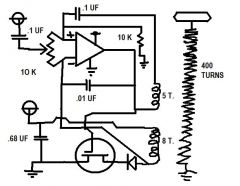

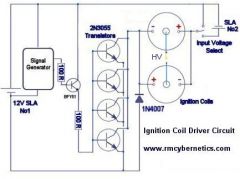

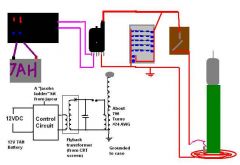

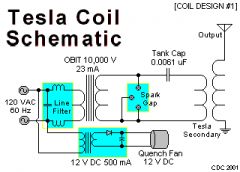

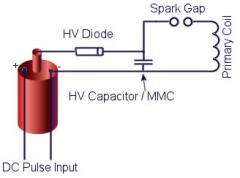

This coil operates from 12V or 24V SLA batteries. A pair of car ignition coils are used to provide around 20kV for charging the capacitor bank. The ignition coils are driven by a variable frequency square wave from a 555 timing chip and four large transistors (2N3055).

|

Input Voltage | 12 – 24V DC |

| Power Consumption | 250W Max | |

| Max Arc Length | 25cm | |

| Output Voltage(approx) | 250kV | |

| Primary Transformer | 2 x Car ignition coils in parallel – 20kV | |

| Capacitor | MMC 20 kV | |

| Spark Gap | 5 x 6mm pipes, Variable | |

| Primary Turns | 850 | |

| Secondary Turns | 850 | |

| Secondary Height | 40cm | |

| Secondary Width | 5cm | |

| Topload | 10cm Sphere | |

| Special Features | Plasma/Flame discharge terminal Battery powered Fully portable Variable coupling Basic power Management |

A pipe from a hole in the top of the sphere and down the inside of the secondary coil is used to supply gas to form a type of plasma electrode.

Using Butane gas and air, a blue flame can be used as an interesting discharge terminal. The heated CO2emissions provide a low pressure channel to conduct the electricity more easily than air. This produces a large plasma column above the flame. At certain spark gap discharge rates the plasma column can be made to resemble a stable double helix formation. Small quantities of other gasses such as neon or helium can be mixed with the butane to produce slightly different colours and effects. The table below should help you find some of the components needed for this project.

Using Butane gas and air, a blue flame can be used as an interesting discharge terminal. The heated CO2emissions provide a low pressure channel to conduct the electricity more easily than air. This produces a large plasma column above the flame. At certain spark gap discharge rates the plasma column can be made to resemble a stable double helix formation. Small quantities of other gasses such as neon or helium can be mixed with the butane to produce slightly different colours and effects. The table below should help you find some of the components needed for this project.

| Component | Max Voltage | Source |

|---|---|---|

| Ignition Coils | ~20kV | Click Here |

| Capacitor Bank | 20kV | Click Here |

| HV Diode | 30kV | Click Here |

| Power Transistor | 400V | Click Here |

| Neon / Helium | n/a | ST Gas |

| Control Circuit | n/a | Click Here |

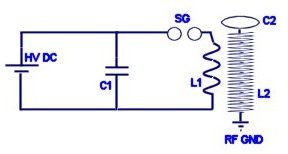

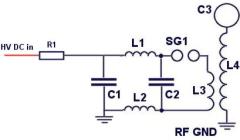

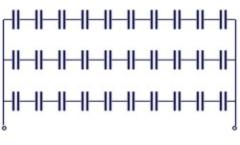

Capacitor Bank – The capacitor used in this project was made by combining a large number of lower valued capacitors. By connecting smaller capacitors in series the overall voltage they will tolerate is increased. To obtain a higher storage capacity (capacitance) the capacitors can be connected in parallel. This type of capacitor bank is known as an MMC (Multi Mini Capacitors). The next version of this project will use specially designed large pulse discharge capacitors. These capacitors can be more efficient than an MMC, but they can be expensive and hard to find.

Capacitor Bank – The capacitor used in this project was made by combining a large number of lower valued capacitors. By connecting smaller capacitors in series the overall voltage they will tolerate is increased. To obtain a higher storage capacity (capacitance) the capacitors can be connected in parallel. This type of capacitor bank is known as an MMC (Multi Mini Capacitors). The next version of this project will use specially designed large pulse discharge capacitors. These capacitors can be more efficient than an MMC, but they can be expensive and hard to find.

Primary Transformer – Ignition coils (Induction coils) obtained from a scrap yard are used for this design. The old ignition coils provide a very cheap way of generating a high voltage for charging the capacitor. The voltage increase in an ignition coil is not determined by the turns ratio like in normal transformers. The secondary voltage depends upon the rate of change of the current in the primary coil. Older ignition coils such as ones from a scrap yard may not work as well as new ones. Over time the insulating oil inside the casing becomes less effective and can lead to internal arcing. This can damage the transistors and the control circuit, rendering them useless

Primary Transformer – Ignition coils (Induction coils) obtained from a scrap yard are used for this design. The old ignition coils provide a very cheap way of generating a high voltage for charging the capacitor. The voltage increase in an ignition coil is not determined by the turns ratio like in normal transformers. The secondary voltage depends upon the rate of change of the current in the primary coil. Older ignition coils such as ones from a scrap yard may not work as well as new ones. Over time the insulating oil inside the casing becomes less effective and can lead to internal arcing. This can damage the transistors and the control circuit, rendering them useless

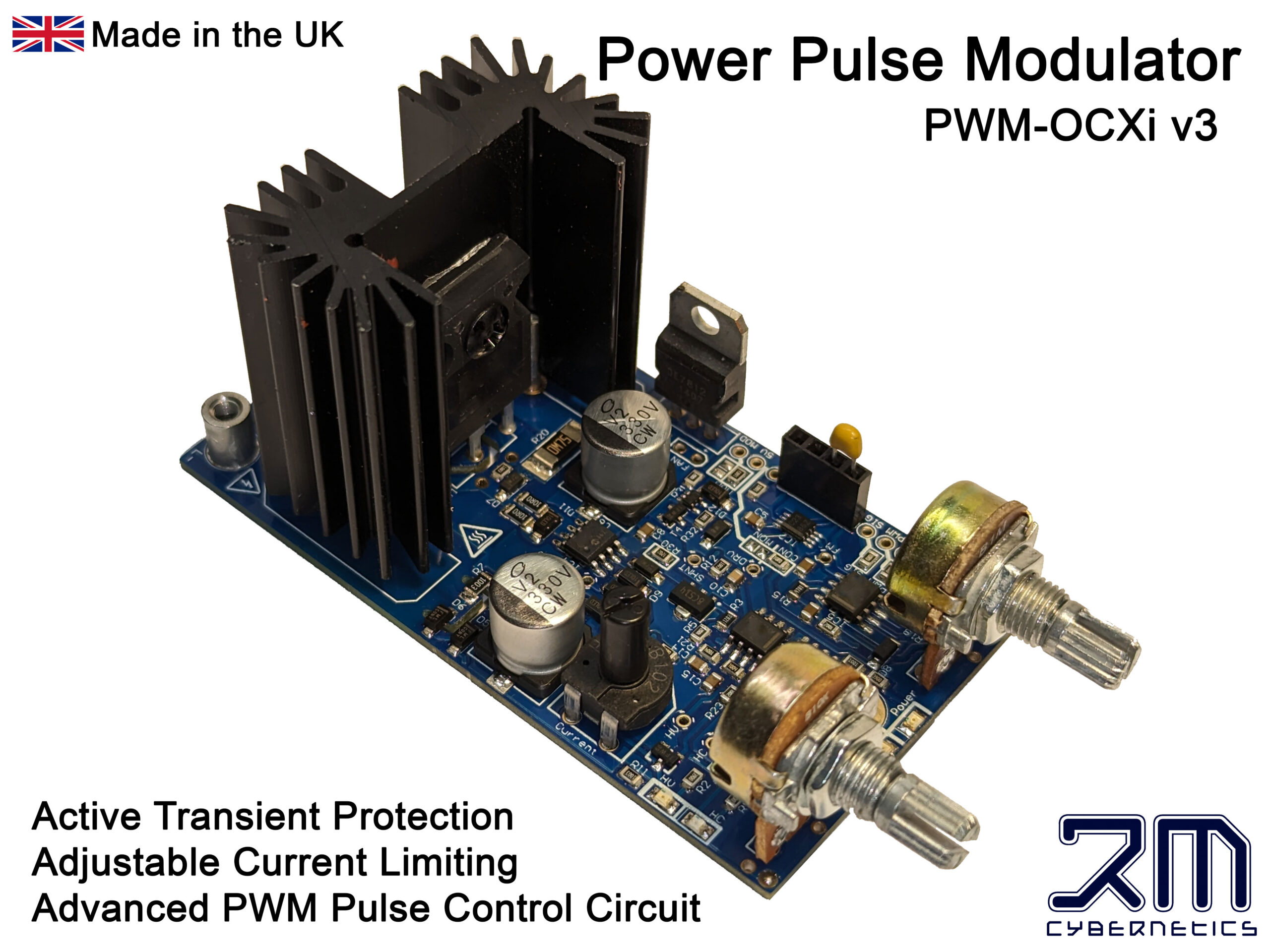

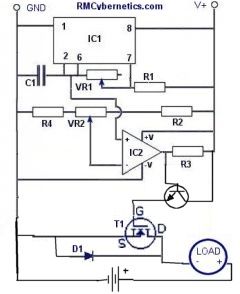

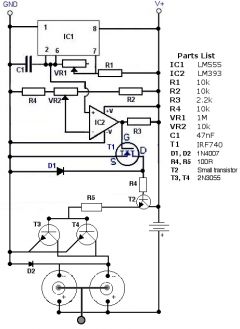

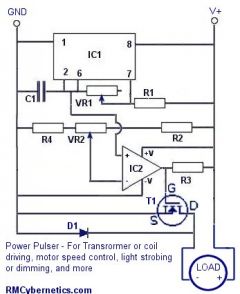

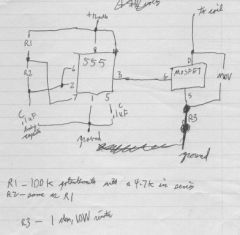

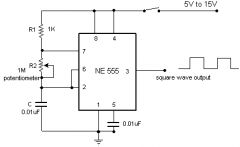

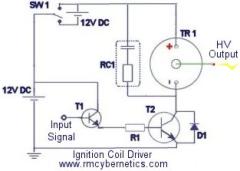

Control Circuit – The control circuit is based on a simple oscillator provided by an NE555 timer chip. The square wave pulses are sent to a set of four 2N3055 power transistors mounted on a large heat sink. These transistors can switch a good amount of power quite quickly, but they can be sensitive to voltage spikes caused by feedback in the circuit, or faulty ignition coils. The Ignition coil driver circuit shown below shows how the signal from the 555 chip is pre-amplified, so that the large transistor array can be driven effectively. Using 2N3055 transistors in this way is not ideal, but it is what we had available at the time for the project. Modern IGBT transistors are much more effective and less

Control Circuit – The control circuit is based on a simple oscillator provided by an NE555 timer chip. The square wave pulses are sent to a set of four 2N3055 power transistors mounted on a large heat sink. These transistors can switch a good amount of power quite quickly, but they can be sensitive to voltage spikes caused by feedback in the circuit, or faulty ignition coils. The Ignition coil driver circuit shown below shows how the signal from the 555 chip is pre-amplified, so that the large transistor array can be driven effectively. Using 2N3055 transistors in this way is not ideal, but it is what we had available at the time for the project. Modern IGBT transistors are much more effective and less

prone to failure from voltage spikes.

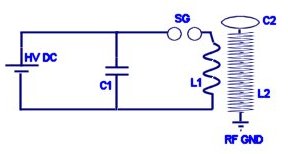

The output from the ignition coils is rectified (converted to DC using diodes) so that it can charge the capacitor bank C1 shown below.

Coils – The primary coil is simply made from 2mm enameled copper wire, wound around a plastic stand. There are six turns in total, but the connection is made at about 4.5 turns when tuned. The secondary coil is wound from 0.4mm enameled copper wire around a plastic drainage pipe.

Coils – The primary coil is simply made from 2mm enameled copper wire, wound around a plastic stand. There are six turns in total, but the connection is made at about 4.5 turns when tuned. The secondary coil is wound from 0.4mm enameled copper wire around a plastic drainage pipe.

Safety – Attached to the capacitor is a short circuit switch that is activated by a long plastic handle. This is used to make sure the capacitor is fully discharged, and cannot recharge whilst making any manual adjustments. There is also a switch to isolate power from the ignition coils that is activated using a insulating pull cord.

Special Features – This project has several extra features compared to a common Tesla Coil. The topload sphere has a small hole to allow gas to be emitted. A 5mm plastic pipe runs down the inside of the secondary coil, and out of the plastic base.

Special Features – This project has several extra features compared to a common Tesla Coil. The topload sphere has a small hole to allow gas to be emitted. A 5mm plastic pipe runs down the inside of the secondary coil, and out of the plastic base.

This allows the gas to be piped in, without interfering with the normal operation of the Tesla Coil.

Future Developments – This project is currently being upgraded. The new design aims to achieve a higher power throughput. By using more ignition coils in parallel it should be possible to increase the size of the spark gap, or to fire it more rapidly. New ignition coils will used instead of the second hand ones for improved stability. The new design also incorporates voltage and power monitoring features. It also has a neat metal finish and multiple outputs so that it can be used as a multi purpose portable high voltage power supply

Future Developments – This project is currently being upgraded. The new design aims to achieve a higher power throughput. By using more ignition coils in parallel it should be possible to increase the size of the spark gap, or to fire it more rapidly. New ignition coils will used instead of the second hand ones for improved stability. The new design also incorporates voltage and power monitoring features. It also has a neat metal finish and multiple outputs so that it can be used as a multi purpose portable high voltage power supply

Are you ever going to sell secondary coils again?

Yes we will. I do not have a date for when though as we have been working on other things.

What about the polypropylene 1kV 330nF capacitors you used for the capacitor bank? Are they ever coming back, or have the been superseded by the high voltage pulse capacitor?

The HV Pulse capacitor is an alternative yes, but we do still sell the smaller ones.

https://www.rmcybernetics.com/shop/electronic-components/capacitors/polypropylene-capacitor-400v-330nf

You wont get a square wave, especially using a spark gap. Magnetic quenching will help, but the coils will still ring in a sinusoidal way.

You can use something transistor based such as our PWM-OCXi if you want very fast rise and fall times.

I want to experiment with pulsed DC at various frequencies on a Tesla coil. If I use a battery for power supply, how can I generate a perfect square waveform, sharp rising and falling edges. Would a magnetic field at right angles to the spark gap help?

David, Your diagram in #4765 looks ok.

Nicole, No, the resistors etc are needed to make the 555 run.

Jakob, You should add ‘bleeder resistors’ between the terminals. These are very high resistance resistors that will slowly discharge the capacitor when not in use.

How can I safely discharge my capacitors?

Thanks,

Jakob

Is it possible for the NE555 timing chip to act as the signal generator on its own? Do we need the IC socket and other resistors?

like this one?

there’s another tesla coil circuit, will that work?

Yes, but it would be better to remove T1, replace T2 with an IGBT, and connect the signal wire to R1. You must also have a common ground between the signal generator and the coil circuit.

I was wondering, will this circuit from the file works? it was a tesla coil circuit

Building my first tesla coil, using this website, and all is going good… if you don’t include the signal generator. Wiring parts up that only had one or two terminals was easy, but I am not sure what to do with six? Have any circuit diagrams that clearly show what to do with each of the pins? Thanks!

Yes, you can just use 30kV capacitors, and the new coils in our shop will work just fine for it too.

could i just use some 30kV capacitors instead of combining a bunch of little ones, also do the ignition coils have to be old and form a car or can i just get some on this website.

The coil is not likely to get hot, but the arcs will be very hot. If they strike or come close to the coil, you may have problems.

For my secondary coil I am using a material which has a melting point of 60 C [140 F]. Will it be alright?

1. No. Any similar high voltage supply will do. You can use one driver to power multiple coils. You just need to make sure that the combined impedance of the coils is not too low or it would blow the transistor in the drive circuit.

2. The Tesla coil primary and secondary coils do not heat up significantly.

Just a few questions…

1. Do you need an ignition coil driver circuit at all? If so, would you need one for each Ignition coil, or one for both?

2.How hot did the primary and secondary coils get during use?

Thanks

This is the best site for electronics I have ever seen. Great work and information, made easy to understand.

drdreads,

This is fine. See the diagrams for this NST Tesla Coil

TW462,

Yes, you would reverse the diode if you reverse the input voltage. You can email the article to me. The legality of that would vary in different countries, but in most it would be considered as fair use as it is only for reference and not to be posted on the website.

Hi RMC, i have a general question relating to ignition coil set up, i’ve seen some schematics that connect the ignition coil back to front; positive supply connects to the negative terminal, negative supply connects to the positive terminal. I have a question regarding this:

You previously advised me on at least one rectifier on the HV output to charge the cap, would an ignition coil wired up this way produce an output that is more negative than positive and require the diode to be reverse biased?

My question is based on a magazine article that didn’t include any rectification on the HV output, it wouldn’t be a problem to forward the schematic but i’m not sure whether that would cause problems with copyright infringement?

Many thanks

TW

hi thankyou for those answers,i find your site very helpful.just to calrify,do i connect the center tap ground of the nst secondary to the terry filter and rf ground still or will this stop me from getting the 10kv output? and should there be a problem and the safety gap of the terry filter fires will this also put dangerous current through the tesla secondary coil?.thankyou.mark..

Neon sign transformers have a centre tapped secondary coil. The middle of the secondary coil is connected to earth which is normally also the chassis.

To get 10kV you need to disconnect any earth connection and take 10kV from between the output terminals.

While it may work to connect the secondary coil to the primary, I would not recommend it. First of all, this would add extra danger to the output streamers as they would be electrically connected to the primary tank capacitor making them capable of delivering deadly current. It can also create problematic feedback when not precisely tuned which may damage your capacitor or NST.

hi RMC,iv been doing a bit of research whilst waiting for layers of varnish to dry on my new coil and it seems that on a few websites they say it is possible to connect the rf ground to the first turn of the primary coil? supposedly this eliminates the risk of primary strikes,need for a dedicated rf ground and increases efficiency due to the fact that if one uses a strike rail then the streamers are attracted to the strike rail somewhat.is this true and what drawbacks are there to this? i was thinking that this may over voltage some of the charging circuit components.and of course an arc is a conductor,so if the rf ground is connected to the primary then theoreticaly the streamers would carry dangerous charging circuit current in them?.thanks.mark..

hi,i have recently aquired a neon sign transformer for use on my tesla coil.its rated 10kv @ 25ma. on the bottom of the transformer theres a plate that says 5kv-0-5kv. and in between the output wires is a small screw with 2 short pieces of single strand wire wraped around it that have been chopped off,im thinking you are supposed to use a 5kv out and a ground? i have used just the 2 wires and ignored the screw for now and it seems to work.am i getting a full 10kv from doing this?and do i need the ground? this is the first NST ive been able to get my hands on so im not sure how they are supposed to be connected up.thankyou..

Maybe you could add a heat sink to the transistor to keep it cool. You may also want to increase the resistance between it and the larger transistors so that less current flows through it.

no that was kind of an update on what i-m doing but now i have a small problem …i’m useing a bc 139 in the bfy51 place …and it gets very very HOT i got blisters on my thinger from it ….can u give me a suggestion

Erm… Is that a question?

omg… since the last time i tried to make the circuit for the pulse generator and the coil driver …and they do not work …shourly i’m makeing a mistake and i think that my coils are burned out or something vecause i do naot getaround 2 ohmswhen i mesure them

Radu,

The first one is typical of an AC mains powered type. The second one uses DC charging. That said, either would work in either situation, but typically the first one is used as it can cause less stress on the transformer.

TW462,

If you have a scope, you should be able to get a readout through a voltage divider. Ideally your caps and diodes should be rated for at least twice the peak voltage of your supply. Sometimes this is not practical, so they should just be as high as possible. The ignition coils I’ve use will put out 20kV when not loaded. The size of cap you use (combined with the primary coil) will need to have a value so that the resonant frequency matches your secondary coil. If you have a look at the three DIY Tesla Coil projects on this site you can get some idea of the size of capacitor relative to the size of the secondary coil.

Thanks for the response to post 4083, on the understanding that the output will be a voltage spike rather than a regular wave, am i going to be unable to measure the output reliably through a voltage divide? If not is there any chance you could offer some guidance on cap values? As it stands i believed a combined rating of at least 20kv should be enough, capacitance of 1.5 to 2nF? Does that seem a reasonable starting point?

that one and this one …. i do not know how to put 2 images on the same post

Have a look around your local DIY store. Maybe a door handle or metal lamp shade would be a good top.

I’m not sure which two diagrams you mean. There’s a lot of different ways you can make a Tesla Coil.

Hello, my name is Radu I’m from Romania and I stumbled across your site some years ago and I never managed to start a tesla coil project of my own. But now I finished collage and I have some free time to spear until now I made a peaty good stand and the coil for the secondary, I’m sorry I do not have a camera right nou to put some pictures. I’ll make it around 12 inch tall with a toroid on top, until now I do not know what to use fore a toroid, a aluminum duct is too big for my 2 inch diameter secondary …

I researched the tesla sites and I’ve came across 2 diagrams and I was wandering if you could tell me the difference between them. I’ll make the wiring like on your site because I’m using tow ignition coils, just like in your diagram.

Thank you, Radu.

An ignition coil works quite differently to an AC transformer like those equations are for. The output of them is a high voltage spike rather than a continuous sine waveform.

Also those equations are meant for charging a capacitor every half cycle so no diodes are needed. With an ignition coil system you must use at least one diode.

If your output voltages and currents are unknown, you are just going to have to determine the best capacitor by experimentation. You will also find that certain frequencies will work best when they match your spark gap firing rate.

I was just reading advice on choosing capacitance values for the capacitor bank and am trying to see how it ties in with an ignition coil driven design. The formula i was looking at required the supply impedance and line frequency; the formula to calculate the supply impedance required output voltage and current of the supply. Now, i understand the equations and that they are only a guideline, but where do you start if you’re using an ignition coil that will produce unknown voltage and current? Also the supply to the coil has a variable frequency, doesn’t this complicate things further? I’ve looked at several similar designs and capacitance averages to approx 3nF between them, i could experiment with this but i have budget restrictions on my project and need to justify my choices. Any guidance would be very welcome, thanks.

While the average output current of the coils is likely to be less than 10mA, they may have a much higher peak current due to the pulse nature of the output. To be on the safe side, I would use the 100mA type as it would save you from possibly having to replace blown diodes later on.

Would just like to say a big thank you for all the information you’ve provided so far, it’s been a really big help. I’m currently developing a system for a college project, 555IC frequency control to a single ignition coil, only difference being the coils are mounted axially and output between 2 electrodes to keep the arc where i want it. Something that i hadn’t considered was the HV rectifier diode between ignition coil and mmc, i was looking at the 20kv diodes in your shop, would the 10ma be suitable or should i consider the 100ma?

Check out our latest Tesla coil Project

Blowing these indicates that there are large voltage spikes on your PSU. Use zener diodes or MOVs across your coil and PSU terminals to limit voltage. SP1 is a MOV. Contact us by email about the diagram.

Hi RM,

I am using the PWM-OC10A I bought, to drive a toroid transformer in open collector mode. It still blew the 555timerIC, LM393 and the 1N4007 diode and the track for the diode.

I am in repair mode now. What is the SP1 component? Also can I get an exact cct diagram to repair it?

Deven

A medium strength field

HOW MUCH STRENGTH MAGNETIC FIELD IS SETUP BY A MEDIUM SIZE TESLA COIL

The airflow from a VDG would not be powerful. It could be possible to partially control a discharge in this way.

can a van de graff generator be used to charge up a powerful flow of air,

and this air stream be made to carry teslabolts ?

if this can be done it will be a true trsla coil gun

Yes, You can use the HV output to charge the tank capacitor.

Can you use Air purifier/negative ion generators to make Tesla coils or power them ive been told u can just need to clarify and a bit of a explanation on the process to utilise them if so

Hi am i able to use the plasma balls that respond to touch and sound for parts to make Tesla related technology there’s a HV transformer int he 2 i have that run off 4AAA batteries and excite the sealed electrode in the plasma ball to generate the effect i figured i might just have all the stuff right in those two plasma balls to make mini telsla coils and power them off aaa batteries 🙂

so I got a thick pusing arc across the spark gap by putting more bottles in. uafortunatley, my secondary was put on hold so I have turned to my sstc. I want to know, would a modified joule theif circuit be an adequit inturupter?

Type your message here

TO JERRY: see coomments No. 3047 and 3075. You do not need groundng at all with bipolar TC.

aldrin,

So many diodes in series is not likely to work. They wont switch at exactly the same time so some are likely to be blown.

That transistor is fine.

JOSEF,

Yes that is correct. The capacitance would be 150nf/12 = 12.5nF

Jerry,

If you are unable to run a wire down the outside of your building to a rod in the earth, there is still an alternative. You can place a wire mesh over the floor under and around your TC. It should be at least several meters wide.

arccrazy,

Seems like your capacitor does not have enough capacitance. Are you sure you have constructed and wired them correctly?

OK so now i have removed the center point ground. I have the transformer in a plastic box and a pvc pipe to turn it on. I am getting closer but not quite there yet. the sparks are either thick white like the ones strait from the transformer, or thin purple ones that dont happen continuisly

How to test ground ?

My studio is located on third floor. I can’t use ground rode or water pipe (because my audio/video equipment dont like it) to discharg spark for change light texture. For now I use long copper wire that I leave on the floor..at the other end of wire (near tesla) I plugged small rode (in my hand) .

Before I try to plug it on outside fence and I never got shock but now in my studio with long copper wire yes ; )

Someone have solution ? or how Can I test ground ?

Merci!

Type your message here:

See please my comment No.3047 (28th Aug 08).Bipolar twin TC and also horizontal TC work very well.Here is the question re TOTAL VOLTAGE TOLERANCE : I am using 12 polypropylene caps in series. Each is 150 nF and rated up to 2000 Vdc(500 Vac). I believe that total V tolerance = 12×2000 V = 24000 V. Cornell Dubilier caps. 942C20P 15K are not cheap, so I would be grateful if you check my assessment re total V tolerance of my caps all wired in series.

can i use transistor IRFP250? thank you

i dont have high voltage diode. can i use 20 pcs of 1n4007 in series? to make a 20KV diode? any suggestion? TIA

An NST is wired a little differently to an equivalent lower voltage transformer. You need to change how you use it. The middle of the secondary coil and the metal core are grounded (connected to the earth cable). You can get an arc between one of the outputs and the earth connection but it will be just 4.5kV. If you want the full 9kV you need to disconnect the earth wire from the transformer.

Note that this is potentially dangerous as the once earthed metal body or brackets are now floating at a dangerously high voltage. You should make sure to put it in a new case to prevent accidentally touching it.

Hi. I need help with y tesla coil’s charging circuit. I have a neon sing transformer at 9 kv and 60 ma. I do not have a rectifier. I can’t get any arc to happen over the spark gap. my capacitor is two wine bottles. It has a gfi but the indicator isn’t going. why? ( the cap is acros the nst.)

aldrin,

The diameter just needs to be big enough to take the current you want to pass. Bigger than that would make no noticable difference.

Deven,

No. They are PNP type, this circuit is for NPN.

Hi,

I have a heap of MJ2955’s. I wonder if I could use them instead of the 2N3055’s for the coil driver.

Thanks

deven

okie thank you. can i use 1/4 inch copper tubing on primary coil? bigger diameter of primary coil can maximixe the output voltage of secondary coil? TIA

Rotary spark gaps are better because they give better quenching

which is better? rotary space gap or ordinary space gap?

OK thanks, I’ll ask him. but i’v been having troubles with my tesla coil.

I have a sgtc with the cap in parralel to the power source. I have a secondary of aporx. 900 turns and a variable spark gap. my power source is a zvs+flyback config. I can onlty get minor puple sparks coming out of the top and none with a topload. (I have tried many toploads) I think I even have the coils tuned.

TESLA CIRCUIT,

I don’t know becasue the important parts are not even labeled.

aldrin,

Non-polar, high current or pulse discharge types. Definatley not electrolyitic, they will explode! Ones made from rolled metal and polypropelene are good. Ceramic ones will also do for small Tesla coils.

what kind of capacitor is use on MMC? polar or non polar? electrolitic or not?

My frein gave me this circuit and claimed it had worked before. I was wondering if you think it would work?

I have limited resources and I dont want to build it if it wont work.

Thanks

Microwave oven diodes are only rated for a few kV. you would need ones rated for at least 20kV. Full bridge is best.

Hey,

I recently received several microwave oven diodes. I was wondering if they would be sufficient to rectify the output of two anti-parralel ignition coils.

Also, how do you wire up your rectifier?

Is if Full or Half bridge?

thanks

Jerry:

I would recommend you just build your own. It’s the most fun way I know!

Yes, you may have to do a little research first, but trust me, it is well worth it!!

You can find most of the information you will need on this site– right under your nose!

Good luck, and HAVE FUN!!!!!

Hi, someone can tell me where I can buy one ? (Tesla coil, assembled or not) It’s easy way I know !

Thank’s for all information !!

a nice simple driver is a ballast circuit to drive a ignition coil its output is very similar to a neon transformer for those making tesla coils

Yes it is very dangerous. A simple mistake could lead to immediate death.

Start small, make a battery operated Tesla coil so that the power levels are limited to non lethal levels. Please don’t mess with mains powered high voltage transformers.

attempting to make a tesla coil using a neon sign transformer with an output of 15kv at 30mA i have no experience with electronics of any kind whatsoever. is this dangerous and what should i do/not do?

Yes.

Do you think a zvs driver+ large flyback could ower this coil?

There are many ways to build a solid state Tesla coil. You really need to research the varieties before continuing.

I am looking to build a solid state tesla coil. I have a igbt rated 1200 volts at 600 amps. Could i use this to power a miniature coil? If so would it work with a ne555 circuit? I dont know how many windings but i assume the 555 circuit would be tunable enough.

Ryan,

1100 turns sounds like a lot for something just 35 cm tall. several hundred should be enough. Having so many turns mus mean your wire is very thin. Thin wire has more resistance and lowers the Q factor of the coil making it waste energy.

When you build a coil you must tune it otherwise you will get nothing. Read through the messages on this site for help on that.

Is your secondary coil connected to an RF ground? This can make a big difference on most coils.

Here is one of my videos of Mini Max. It’s short (only 23 seconds or so) but it should give you an idea. As a topload, I have a 1 inch diameter steel ball bearing.

Hi, I just finished building a coil. Its got about 1100 turns of thin copper wire on a PVC pipe thats 14 inches high and about 7 turns of copper tubing for the primary (pancake type). The spark gap is made of 2 adjustable bolts. Cap is a bank- made up of 10 x 2kv 47nf ceramic disk type caps. Whole thing is powered by a 9Kv 30ma NST. Everything is hooked up and when i turn it on, the gap fires but no sparks from Toroid. Would be really greatful for some help. What am I doing wrong here? I tried holding a wire connected to the bottom end of the secondary close to the torroid. But still no sparks or Corona.

Woops! sorry. the pictures didn’t come through. Here are a couple of pictures of Mini-Max while it’s running. More to come!

Der Strom

Glad to hear of your success. If you want to post a video. Uplaod it to somewhere like youtube, then post the link in your message. The moderator will embed the video into your message.

This is it! Mini Max, my ultra-tiny tesla coil! I was planning on posting pictures of Max, my mini tesla coil that I described a little while ago, but Mini Max performed much better. It is a small cardboard tube wound with roughly 300 turns of ~28 AWG wire that I pulled out of an old motor. It uses my 9 kv, 60 mA NST with a single beer bottle capacitor giving a capacitance of only about 0.7 nF. Mini Max produces an estimated 100 kV from the 9 kV input. I will post more pictures and possibly a video (if it is permitted) of Mini Max’s performance. Unfortunately, the electric field from this tiny tesla coil is so large that it sets off my answering machine and my smoke alarms if I run it too close.

Thanks for all of your help!

Sincerely,

Der Strom

jango,

Yes, RC1 is useful in any ignitioncoil application to snub spikes.

Yes you can connect directly. The number of turns depends upon the voltage and frequency and duty. You just need to make sure that the current draw does not exceed the ratings of the PWM-OC10A

John-Paul,

Wow, that is quite an extreme version of a battery powered TC. Try placing a MOV or TVS (rated for some voltage below the rating of your transistors) between the C and E of each transistor, or between the inputs of each coil. Note that they heat up as they absorb over voltage, so keep an eye on them. Not sure what you mean by a ‘cap soft start’

Der Strom,

Just google for “Comparator test circuit” or something similar.

jango,

Yes, RC1 is useful in any ignitioncoil application to snub spikes.

Yes you can connect directly. The number of turns depends upon the voltage and frequency and duty. You just need to make sure that the current draw does not exceed the ratings of the PWM-OC10A

Then I of left PWM6OC10A to connect a flyback directly? How much turns of copper wire have I to roll up (12? 30?) Thanks

Hello. Then I to directly connect a flyback and a PWM OC10A. Thanks

I just put together the circuit you posted (thanks, by the way) but I’m not getting any output from either of the 393s that I have. I am getting an output from my 555, but nothing from my 393. I’m sure at least one of them isn’t burned out. Do you know what might be wrong? Is there a way I can test it?

Thanks a lot for your patience!

Sincerely,

Der Strom

Hi I am almost ready to test my coil that is based around your batt powered twin ignition coil setup. I am useing 2x 100amp 12v car batterys 20x 2n3055s on a cooling bridge, a low inertia RSG with speed control and 30kv cap, as well as a load of 30kv diodes for the pararelled 8 to 12 igniton coils. the tesla coil is for my art degree in the final uni show and i wanted to use a large amount of ignition coils for the asetic but I am haveing lots of problems with feedback destroying the tranistors. I would also like to create a cap soft start from the 2 batss but not sure what the values would need to be. Can you help me with some sort of feedback prevention circuit as well as help with the soft start caps… thank-you this site rocks!!!

For this diagram is necessary it to include system (R-C1) between the D1 diode and the ignitions coils to avoid a tension of breakdown? thanks

T1 would be your array of 2n3055’s or other transistors

WHOA!!! Thank you sooo much for pointing that out! That’s probably why another circuit I’ve used isn’t working very well.

How is your circuit connected (I assume you are using the power pulse generator with PWM and the ignition coil driver that you showed at the top of this page)?

Thanks, once again for pointing out the incorrect connections!

Sincerely,

Der Strom

We don’t sell either of those items. You can get them from most electronics stores.

(1) where could I buy, on your site the radiator for 4 transistors 2n3055 (2) the diode is it special see 1917 DER STROM thanks so much

der strom,

You should not connect your PSU in series with the load. You should link the grounds (0V) of the PSU’s , then connect the +ve of your load to the V+ of your high current PSU instead of the other.

The current drawn is dependant upon ohms law. The impedance of your load limits this current. Even if you PSU was rated for a million amps, it would still only supply 1.7A.

The second diagram wont work. The way you add T2 is all wrong, so is the way you connect the second power supply.

Jango,

Not really sure what you are asking.

then I to transform an amp-mêtre (1_5 A) in volt-mêtre (10kv -50kv) or in frequency-mêtre to test a PWM. thank you and better greetings

Sorry, forgot to post this.

Would this circuit work, or am I missing a few key components (it’s a combination of your power pulse generator and the paralleled ignition coil driver)?

Thanks!

-Der Strom

I finally got hold of a 15 volt, 5 amp power supply (also for a computer) and connected it in series with the “load” shown on the circuit, but the flyback transformer is only drawing 1.7 Amps from the 5 amps supply. Do you know why this might happen? I was wondering if I should just add in another transistor to switch the power supply instead of just connecting it in series with the load. That way I assume I’d lose less power.

Those equations are typically designed for side wave AC power from mains, so if you are not powering it like this, the result will be invalid.

If you use a diode, you should calculate the RC time constant to charge your capacitor to the voltage you want. i.e. You can find what capacitance will charge to the voltage you want in that time.

Thought I might mention:

I tried running my tesla coil without a high voltage diode after the ignition coil and, using a single beer bottle capacitor, I got faint streamers to air about 3 cm long. I just connected the circuit like the ignition coil was an NST, and it still worked. I assume, though, that since it wasn’t DC, and the capacitor charged every half-cycle of the ~20khz output of the ignition coil, the capacitor was unable to charge fully. Because of this, I could not have a very wide spark gap, and therefore, I did not have a good output from my TC.

I plan on getting a bigger, better heat sink and possibly a battery-powered fan that I can just “plug in” to my solderless breadboard that I currently have the circuit on, directed straight at the MOSFET to keep it cool (or cool-ER).

By the way, I used the equation on deepfriedneon.com for the capacitor/transformer match, and after filling in the equation with my own information (i.e. a different frequency other than the 50/60hz.), it said I would need a tank capacitor with a capacitance of 69nF. Does this make sense? My flyback transformer delivers about 15kv at about 15mA (maybe as much as 20mA).

Thanks a lot!

-Der Strom

jango,

Yes a pwm is ideal. No you cant use a spark-gap (eclateur) instead of RC1. Please use the translator I mentioned to you before.

der strom,

Glad you like it. Keep an eye on the temperature of the heatsink if you are going at 5A.

Oh, by the way, your Power Pulse Modulator works GREAT with my flyback transformer. Even with only 1.1 Amps of input voltage, I get nice, long, HOT arcs that I can draw out to about 3 cm! I can’t wait to see what it does with 5 Amps of current!

Oh, I forgot to mention that I’m no longer using the transformer driver that I posted above. Now I’m using your power pulse modulator with my wall adaptor power source in series with the flyback. It works GREAT!!!

Sincerely,

Der Strom

in his message 1940 DER STROM show a schema can i replace RC1 by a “”eclateur “” may be a sparker to avoid overcurent

thanks

i read that write DER STROM bout tesla coil it is a lot of very goods things

i d’nt find if he use a PWM OC10A

for drive ignition coils

in a schema see in ” diy tesla coil ” may i use a PWM as signal generator

thanks

sorry my ENGLISH is a broken english

I have found on various other web sites schematics of a DC Tesla coil that include a 20mH charging choke between the HVDC power source and the tank capacitor. Would this improve the output of the tesla coil?

No, 1.1A is very low. About 5A or more would be best.

Right now, It is running off of an 18 Volt, 1.1 A wall adapter for an old printer. I’m not sure if it is taking the full power, though. If it is, is 1.1 A enough?

How many amps is it drawing from your battery when it is running?

MY FIRST WORKING TESLA COIL!!!!!

Within a couple of days, I took the wire from an old MO fan and wound it around a cardboard (didn’t have any plastic) tube and got about 650 turns. For my primary transformer, I used a flyback transformer and the driver shown above, taken from somewhere on michaelv.org. Since the flyback already has a built-in rectifying diode, I did not need the 16kv, 300mA diode I found in another MO. I plan to use this with my ignition coil. For my primary coil, I used 7 turns of 3mm diameter stripped copper wire, tapped at about 5 turns, mounted on 4 cardboard supports in a steep conical shape. I used 3 beer bottle capacitors, giving me a capacitance of about 2.5nF. For the topload, I used an 8cm (yes, centimeter) diameter aluminum pie plate flipped upside-down. Right now, I am getting 5 cm streamers to air (only visible in extremely low light), but only 1 cm sparks to grounded screwdriver. I was wondering if you knew why I’m getting such small sparks to the grounded screwdriver. I’m sure it is a good ground connection. Thanks for your help, as always!

Sincerely,

Der Strom

Yes, that is plenty. Matching the freqencies is more important.

I’m not sure if you ever answered my question in post #3103 on this page. I also just realized that with thinner wire, I would have gotten MORE turns. So my calculations must have been off. Do you think 700 turns would be enough, since it uses resonance rather than the turns ratio?

Thanks!

Zensunni,

There are many such example on the net allready. I would reccomend googling for NST tesla coils.

tesla fire,

Yes. The thickness of the wire depends upon the amount of current you want to pass through it. it is bes to be too thick than too thin. Copper pipe is a common choice.

can polyester sheets be used to make capacitors?

what wire can be used to make primary coil? what is the minimum awg value of the wire for this application?

I am seeing alot of flybacks diagrams as a power supply however I am going to use a 9k nst@.03ma. What would be the best set up? and if possible please include a diagram. thank you very much for any help.

909,

A capacitor stores energy not charge, you will need a diode unless you discahrge it betweemn each half cycle of the AC current

IF DR TESLA WAS ALIVE TODAY HE MOST CERTAINLY WOULD HAVE BEEN PROUD OF YOUR EFFORTS.

can a step up transformer be used to store charge in a high voltage capacitor? will i have to use high voltage diode?

Thanks

Great advice

awesome site!!

You should have a large space between the primary coil and your metal case. The oscillations in the coils will induce eddy currents into the metal case which would waste energy as heat.

It looks like you have a lot of primary turns. It might be better to use less turns and with thicker wire. You would have to increace the capacitance of yout tank capacitor to compensate and allow it to run at the sme resonant frequency.

Also make sure all high voltage parts (such as the capacitor terminals and flyback lead are kept short and well insulated. You could insulate any bare HV metal using thick epoxy.

Here is a pic of the schematic, for the previous comment.

Here is my tesla coil.

It is currently running off a 12V 7AH battery that is about 2 years old.

It is powering a CRT flyback from a TV, which has an internal diode in tact.

The cap bank is made of:

6 paralell strings of 5x3KV caps in series. Their capacitance varies.

There are 2 30KV 1nf caps in parralell with the first caps.

The spark gap is simply 2 metal rods put close to each other that can be adjusted. It works well.

All of these components are mounted in a metal computer case. This is ground for the secondary and the -0v of the primary coil.

The computer case is ventilated with the original fan, connected to a 9V battery inside the case, with a switch mounted on the case.

The primary coil sits on the case, and has a tapping clip to connect it to a tapping point on the coil. It is currently tapped at 3.3 turns.

The output is 1.3 cm plasma to air, and 7cm sparks to screwdriver running off a 12V power supply (from 240V mains). I understand that this is unsafe, but the battery gives about 3/4 of that output.

How can i increase output or improve design? Thanks

instead of using cylinder ignition coils try using the ones that they use on v6 engines they put out 25000volts at ruffly 5 amps.

Very low. In the microamps range.

what is the amount of current in secondary coil during discharge?

black bird,

No, the voltage output is not proportional to the number of turns. There isn’t really a minimum current, it would depend on what you are trying to do, more current, more sparks.

Anyone knows if the altra scienza works?

I used to download pdfs from emule … but it seems that it stoped … anyone knows ? … or some other like this?

Very good about Alternate energy with Tesla and free energy 😉

what is the minimum current required as input to drive tesla coil if we can ignore voltage?

in the above shown apparatus “Secondary Turns is 850”. is increasing the secondary turn to 3000 going to help me to get higher voltage? is there a limit to the number of turn in secondary?

After wiring my 2-foot secondary coil, I realized that I had slightly thinner wire than I had wanted. Because of this change in wire diameter, my secondary ended up with roughly 700 turns rather than the 900 that I had calculated. Do you think my tesla coil might still work, or will I have to redo my secondary coil?

I appreciate all of your help and patience with all of my “somewhat dumb” questions, and I want you to know that you have helped me a great deal with my journey to understanding high voltage electronics.

Once again, thank you soooo much for all of your help, and KEEP UP THE GOOD WORK!!!

sincerely,

Der Strom

Not really, You would need a physically larger device and components for higher power levels.

is it possible to acquire mega volt spark using the same setup shown above?

what should be changed for output of 10^6 volt?

Series, add voltage. Parallel, add current

what will be the output current and output voltage compared to input current and input voltage if i connect transformers in

(a)series

(b)parallel?

IT takes mains input of 220V and gives two 6V outputs. This is a step down transformer. You can connect as many as you like in parallel.

what does “I/P 220V~50Hz

O/P 6V x 2 600 mA” means?

i found it written on a transformer.

how do u connect transformers in parallel?

how many step up transformers can i connect in parallel and still get spark?

HORIZONTAL BIPOLAR TC powered by battery

With bipolar TCs RF grounding is not necessary, because the second half of a bipolar has about the same function as the ground in a typical vertical TC (consequence of symmetry). The horizontal bipo is electrically similar to the twin (see No. 3047). The geometry is different. There are not two vertical secondary + prim. coils but only one continuous-wound secondary mounted horizontally with the primary mounted over the center of the secondary coil. The center of a primary winding is marked 0 with an equal number of turns each side of center. The tuning is done from the center of the primary by an equal number of turns each side of center marked 0. The voltage rises to a maximum at the ends of the secondary c. where the sideloads with the “rabbit ears” are. The sparks travels between them.

My favourite horizontal bipo – in nutshell :12-24V battery / sq.w. oscillator 555+393 /

4 x 2N3055 / two ignition car cs.-antiparallel / HV diode = 60 x 1N4007 in the tube filled with mineral oil / SG=copper tubes+fan=3 x 2mm gaps / primary cap. 7.9nF /

Secondary: PVC tube 60mm OD, 950 turns of 0.33mm(28awg). Sideloads: tin biscuit circular containers 19cm x 10cm. “Rabbit ears”: 2-3mm wire, well insulated by vinyl tubing to eradicate corona. Primary: helical, PVC tube 160mm OD,

8 turns-0-8 turns of insulated HiFi flat cable (8awg). Taps: 4t.-0-4t.

Performance: up to 22-23cm (24V bat.) and 18-19cm (12V bat.).

Yes, You can use a rotary spark gap for high voltages, or a magnetic interrupter (commutator) for low voltage.

Well this is probably a stupid question (i look pretty dumb in the company of someof the people here). I have been experimenting with huge layden capacitors and electrostaics for years .Im am very interested in making a tesla coil in its simplest form. Can you tell me is it possible instead of using Electronic ignition coil driver circuit can i use mechanical means to generate the pulse (as in old fashioned car distributor points)..?

BIPOLAR HORIZONTAL AND TWIN BIPOLAR TCs

I have been inspired by this excellent web pages to do experiments with small TCs. However I am making not vertical TC but bipolar horizontal and twin TCs only. They are efficient and portable because there is no need for any Rf ground. Providing that you choose right coupling and tune precisely, all racing sparks should be eradicated.

Best performing is TWIN BIPOLAR – in nutshell:

12 – 24V battery/ sq.w. oscillator 555+393/8x2N3055/ two ign.car cs. antiparallel/ HV diode=80x1N4007 in the tube filled with mineral oil/ SG=copper tubes+fan=3x2mm gaps/ primary cap. 12.5nF./

Twin TCs: Secondary=70mm OD, 850 turns of 0.33mm(28awg). Both coils were made identical as best is possible, wound in the same direction. Toploads: tin circular containers 19cm x 10cm and you get as a bonus Danish biscuits. Primary: helical 20cm OD,

8 turns of insulated HiFi flat cable (8awg). You can wind primaries either in the same or in opposite directions.Taps at 5 turns on each coil. If you wound primaries in opposite dir., you have to tap only one primary coil at the beginning and at the end of winding (1 and 8 turns).

Performance: 27cm streamers (24V). You can get thicker streamers by using of four toploads in the “double-decker” arrangement and retuning. Providing that all four identical toploads have sparking tips you can get double, parallel, horizontal streamers.

Just few cm at a guess.

what distance would you suggest for my tesla coil (4 inch secondary diameter, input power of 540 watts)?

10cm (~4 inches) does seem a bit far unless the input power is very high. Closest point was about 2cm in the coil shown here.

It’s me again. I’ve pretty much finished with my 4-inch-diameter-secondary tesla coil, but I am having trouble getting it running. I know I have roughly the right capacitance, pretty sure that I have a good ground connection (3 foot piece of steel pounded into the ground), and a good transformer (that matches the tank capacitor), but I am not getting the slightest bit of corona out of the topload. I was wondering if it was a problem with the coupling (my primary coil is a conical primary at roughly a 10-20 degree angle), because the very bottom of my secondary coil is about 3 1/2 inches-4 inches from the primary. Is this too much? I plan on chopping off the extra pipe at the bottom of my secondary coil to bring it closer to the primary. I also plan, if I absolutely need to, on winding a new primary. What do you think the problem is? Could it be the coupling? Thanks again!!

Sincerely,

Der Strom

No, Usually a wider coil is reccomended. It was actually 5cm wide, (I just updated the table at the top). I chose this width just because it is the size of pipe I had available at the time.

Wider is often bettter, but you have to have it tall enough so that the output isn’t to close to the bottom end. You could probably get a similar output from a coil that is half as tall and twice as wide.

I noticed your secondary is only about 3cm wide. Does having a thinner secondary make the output stronger? Why did you choose this width?

der strom,

An op amp requires 2 connections for power which are usually marked something like Vcc and Vee (Vcc is +ve). The two inputs are for a signal and will take a positive or negative input. If you make the non inverted input go high, the output will also go high, but if you make inverted input go high, the output will go low. The comparator compares the voltage on the inputs and determines if the output should be high or low.

I’ve had some success in building the ignition powered coil, just like to share a few tips for anyone thinking of building one. After wiring it all up I got big flash overs on the rectifying diodes so I used resin (from making GRP panels) to ‘pot’ the diodes and I also used heatshrink on the connections. This stopped the flashovers and the spark gap was then firing well – but nothing from the topload after a lot of tuning! The only thing left was a trying a better RF earth (i’d just been sticking the wire from the secondary in some damp earth). So I got a 10mm dia ally rod, stuck that in damp ground and jammed the RF earth wire onto it. Tried it out and got plenty of sparks from the topload. So, couple of things to try there.

I did a Google search for the IC mentioned in my post number 1852 (BA6993) and found out that it is a dual comparator. One of my other projects uses a dual comparator (like an LM393), but the datasheet says that pins 2 and 6 are “INV.INPUT1″ and INV.INPUT2”, and pins 3 and5 are “NON-INV.INPUT1” and “NON-INV.INPUT2”. I know that the “INV” means “inverse,” but I am a little confused about which one means positive and negative: “INV” or “NON-INV”? Thank you so much for your help, and I’m sorry if this is in the wrong category for the question.

what would happen if a lightning bolt fell on a tesla-trooper

I would suggest trying different capacitance values for your tank capacitor as it is probably simpler than making a new primary coil. If you capacitor is made from several in parallel, try just using one and trying different tapping points, then two, and so on.

Ok, I have cut the secondary down to 40cm, and tried different numbers of primary coil windings, but i have still acheived the same result; wirey sparks to a grounded object. do i need to dramatically increase or decrease the number of primary coil windings? as i am using the same tappable primary coil. thanks

I did the exact same thing with this coil when I first put it together. I just got a hacksaw and cut it down to 40cm. If you are careful, you will only damage the windings right where you cut, you can then unwind a few turns and tidy it up again.

What size would you reccomend?

Thanks, great site!!

Here is my tesla coil secondary, shown next to a 12 inch ruler. Is there any way I can change the size of this coil without damaging the remanding windings?

Yes, it sounds like it is too long and thin. Make it shorter and re-tune it.

My 12v SLA battery powered tesla coil is giving weak sparks,in the dark the output is a few feint streamers about 4mm long. It is very similar to your design, but the secondary is about 7cm x 70cm. Could having such a large secondary coil make the output too weak? Do i need to make my secondary smaller?

Thanks for your help

I HAVE READ ABOUT TESLA COILS IN YOUR WEBSITE AND THE INTERNET. I WANT TO KNOW HOW DR TESLA USED A TESLA COIL IN WARDENCLYFFE TO TRANSMITT ELECTRICITY CURRENT WIRELESSLY.

IF DR TESLA COULD DO IT USING THEN YEARS TECHNOLOGY , IS IT POSSIBLE TO BUILD ONE TODAY,?

produc this HV voltage dubler DC high voltage.

3mm should be fine for making it work.

I’m sorry, I must have the wrong number gauge. This wire is roughly 3mm. thick (without coating). Maybe it’s 12 AWG. But anyway, would 3mm. diameter wire work for a tesla coil, or wil it (again) have too high of a resistance? Sorry about the wrong size.

Der Strom

I think 1mm diameter wire (18 AWG) is a bit too small. The resistance of such a length of thin wire would lower the ‘Q’ factor of the system and dampen oscillations. If this is the thickest wire you have, you could take four lengths, put the ends in a clamp, then twist the wole lot to form one thicker wire. I find a hand drill is useful for doing this sort of thing.

After some more calculations (which I hope I don’t have to follow exactly, like you said), I found out that my tesla coil needed a primary coil wound with wire or pipe that is at least 1/4 inch diameter. However, since I didn’t have any, I just used standard 18 AWG house wire (stripped). Do you think this will still work, or will there be too much resistance?

As of now, my tesla coil still isn’t working, and I am wondering if that is the reason. Thank you!

Skappy,

Any Bipolar, NPN transistor rated for about 1A will do.

der strom,

Don’t rely on your calculations. You will always need to tune your TC after it is constructed as there are many factors the calculations don’t consider. You should make your primary coil longer (more turns) than you calculated for and make it using uninsulated metal so that you can adjust the effective number of turns.

That is what I figured, but I thought I would ask just to make sure. In my calculations, I figured out that I would need 14-15 primary turns with a completely vertical helical primary coil. After measuring out all of the wire, however, I switched from a vertical primary to a conical primary, and I only got about 11 turns. would this be enough, or should I measure out more wire and re-wind the primary coil?

Hi,

I encounter difficulties in finding a BFY51 transistor. May i ask you others reference which could do the same job ?

Thank you very much

More turns. Think of it in terms of a place to store energy. I you can store less in your capacitor, then you can use more tuns instead to store it in the magnetic field.

This only works practiaclly to a certain extent because more turns means more inductance which equals more reactance against the flow of changing current. it should not be a problem as long as your number of turns is less than around 20.

N3rD:

I have an ignition transformer very much like the one you describe, and it it used to ignite the fuel in an oil-burning furnace. Yes, the output is AC.

RMCybernetics:

If my tesla coil capacitor has a slightly smaller capacitance than I really need, would I make up for it by tuning the primary coil to greater or fewer turns?

My 4-inch diameter secondary Tesla coil is almost finished!!! I just need this last bit of information. Thanks!!!

N3rD,

I would think the output is AC.

Anyway, a transformer needs an AC input so putting a rectifier before its input will prevent it from working. if you want a DC output you would put a high voltage rectifier on its output.

before i forgot, the coil was suspended in the solvent for a couple of hours, to let the solvent diffuse into the coils

YES! I finally have a economical approach to get a lot of enameled wire from the lamp choke! I suspended the hard coil(don’t know why,maybe it is glued together) into a little of industrial solvent(60% aromatic hydrocarbons,30% ketones , 10% alcohol),and the coil become soft and loosens, and it was ready to use!

Hello,

I am currently starting work on a small tesla coil (4 inch secondary). I found an ignition transformer on Ebay that uses a 120VAC standad wall input and has a 10kV, 23 mA output. I am awaiting a response from the seller to see if the output is AC or DC. It could be either because it is in an enclosure similar to an older NST, so there could be more in there than just the transformer. If it turns out to be DC ouput, do I need the driver circuit? Also, if it turns out to be AC, could I put a bridge rectifier in between the wall plug and the primary?

Thanks so much!

Yes

Is it possible to put two TV flybacks is parallel to acheive a greater charging current?[then using it for a power supply]

Thanx

How do you “tune” the Tesla Coil?

Clean hands, a bottle of cyonacrilate (super glue), some tape, patience.

Start by taping the end of the wire to your secondary former. Put the reel of wire on a roller like a pen in a clamp.

Try to keep the wire tight at all times to prevent it unraveling. Turn the former with one hand while using a finger or thumb of the other hand to press the wire onto it. Push the wire against each previous turn so that he whole thing stays tight.

Every so often put a tiny spot of glue so that it wont unwind too far if you slip or drop it.

Thanks.

Do you have any suggestions on how to wind the secondary coil? I just want to know before i start.

Attached is a photo of my priary circuit. The Ice-cream container on the right is the HV filter, the PVC tube in the middle is the secondary coil(unwound) at the front is the Spark gap (with quencher and it’s power supply), to the mid-left is the Cap bank (in oil) and to the back are my Ignition Coils. It is almost ready to run (after tuning). BTW-great website!!

hellforce666,

Theoretically yes, but you would need loads of them which makes it very impractical.

Frank,

If it is allready smooth, then there is no need. Some varnish after may help though.

I am making a Tesla Coil (3×26 inch secondary) that is powered by ignition coils. Should i varnish/waterproof the PVC coil-form before winding?

hi everyone i’m fasinated by the sparks and i want to build a tesla coil 2

here’s my question: can i use a large set of AA batterys instead of a SLA?

NST

I hav buld a new tesla coil. I hav a 2000V 850mAM MOT 3 2000V 82nF caps in serie. I vil hav a new HV transformer for the tesla coil. Can you help me were is the best transformer to use OBT or NST.

Got it, Finally! my cup capacitor was too small, so I got some soda bottles and made capacitors out of them, and put 3 of them in parallel. Now it works perfectly!

Yes the capacitor should make your gap fire much slower and wih a brighter hotter flash.

I connected my homemade “cup capacitor” with the spark gap, and adjusted the gap so that it actually fires almost like it would without the cap. Originally, when the capacitor was in the circuit, the power seemed to be going through the capacitor, and not the gap. Now that it fires, would it work with the tesla coil? Isn’t the capacitor supposed to make the spark much brighter and hotter? Thanks for the help (once again)!

Measure it with a multimeter or calculate it based on size and spacing of plates. Formula via google

what is the best way to find the capacitance of a home-made high voltage capacitor?

Kan I take 2000V 1000Fp TV caps

Your capacitor is faulty. Yellow light is internal arcing and will only get worse.

I HAWE BULD A Flyback powered Tesla Coil. I HAWE PROBLEMS WIDE MAY MMC. I CAN SE A YELOW LIHT IN THE CAPICOR.

The only way to change the frequency is by altering the value of L or C (coil or capacitor).

Well, I made my own “party cup capacitor” by wrapping foil around a large plastic cup and stacking them one inside another until I had a fairly large stack, and I was wondering if it would be possible to use this cpacitor and change the frequency by doing something else. I’ll try to post some pics of what it looks like from a different site.

these are the pictures that I based my capacitor on. they’re from

http://www.altair.org/tesla.html

You can either make a capictor at that value by combining values of others, or you can get the closest equivalent, and then tap your primary coil to get the right frequency. 0.0068uF is equivalent to

6.8nF or 6800pF. Seven of these caps placed in parralel would give around 7nF. For the same frequency with a larger capacitor you would need to tap your primary so it has slightly fewer turns (or a fraction of a turn).

Using the calculator on

http://deepfriedneon.com/tesla_frame6.html

I found out that for my tesla coil, I will need a capacitor that has a capacitance of .0068uF. My problem, though, is that I can’t find a capacitor rated for a high enough voltage and that has that capacitance. Would it be possible to use one of my own homemade high voltage capacitors (probably not .0068uF) and change the primary circuit’s frequency by doing something else, like tapping the primary coil in a different place?

Of course. I understand. Thank you very much for your help.

You still need to match your primary and secondary circuits to resonate at the same frequency.

ok, so if I have the right capacitors and everything, this would work?

Yes, this coil is powered from mains. The mains provides a high current sine wave. This is not rectified on the output because the capacitor is charged by each half cycle of the power (120 times each second in US or 100 times in Europe).

regarding posts 2625 and 2626, I found this tesla coil circuit powered by an oil burner ignition transformer, that doesn’t have anything (that I can see) that rectifies the output of the transformer. Is there something else in the circuit that I don’t see?

OK… thanks, I think i get it.

This page is fine for your question. Normally the filter would go directly before the load (such as a transformer). It would be better to have a separate spur from your new breaker box which is filtered. You could also do as you suggest as long as the total load does not exceed the ratings of the filter.

Sorry, this is probably in the wrong category.

I was just looking through your shop and i found the line filter to protect the mains from tesla coil frequencies. I was just wondering: would it work to put the filter between the already-existing breaker box in my home and a new breaker box in my workshop to keep the high frequencies from my workshop from getting to the house power?

thank you very much, and again, i’m sorry for posting this in the wrong category.

Either is fine. Google will help you find examples.

I have 2 ignition coils in inputpower. I’m not sure about my plate capacitor. I think it doesn’t work/build wrong. wich is beter salta water capacitor or plate cap and do you have picture how to bild working salt water capacitor or plate capasitor?

It is probably not tuned, or the input power is too small.

Why my tesla coil does not work. It gives about 5mm arc to my screwdriver when i thouch topload. I have home made plate capasitor but idon’t know what is capacitance.

secondary:

Diameter=75mm

turns=920

wire diameter=0.45mm

Primary:

Flat Spiral Coil

wire diameter 1.5mm

coil inner diameter=100mm

turns about 13

No. The ferrite core would lead to too much coupling and would also cause losses due to eddy currents in the core material.

Lots of insulation would also introduce losses. A Tesla Coil works at a much higher frequency than other transformers so even dielectric materials will effect things.

Using a loosely coupled, air cored transformer allows a relatively high Q factor to be achieved.

Would it be a good idea to add a ferrite core to my secondary, provided i insulated it well, perhaps in a tank of oil, and spaced well away from the inner walls of the sec tube?

do you think i would gain any benefits from this setup, perhaps increaced power due to the better coupling, or maybe this could be the basis for a larger magnifier.

Great. Thanks

You will need a HV diode to charge your cap from your transformer.

I tried to charge a capacitor with my oil burner ignition transformer, but it wouldn’t work. I’m guessing that the output of the coil is AC, but i’m not entirely sure. do you have any ideas? I found this picture of a transformer that looks a little bit like mine (if it will help).

Thanks!!!

The Capacitor is absolutely essential. Read about how a Tesla coil works. Energy moves back and forth between the capacitor and the primary coil at a fundamental resonant frequency.

by the way, this is the circuit I tried, but it blew (BOTH) 555s that I had.

I have one more question:

In a traditional tesla coil, there is a static spark gap and a capacitor. Is the point of the capacitor just to make the gap fire at just the right rate, or is there another purpose for the capacitor?

If I had a rotary spark gap with the contacts spaced just the right distance around the wheel (making the gap fire at just the right times), would I be able to run a tesla coil off of that, without the capacitor?

thanks very much for your help and info!

The image upload feature has now been upgraded to allow most common image types and will accept larger sizes too.

All the info I can give you on voltage spikes is on the ignition coil driver page.

I had a pic of the circuit but it wasn’t jpg, so i couldn’t post it on the page. sorry.

Is there a way that I could protect my timer from voltage spikes?

thanks!

Could be one of many reasons. Most likely a voltage spike.

I tried this circuit, but my 555 timer “popped”, and some gooey substance started seeping out from the base of one of th legs. Do you have any idea why?

thanks!

No idea of the capacitance of a CRT. The TC here had only 15nF capacitor.

What is the capacitance of computer monitor crt tube. i have some HV capacitators, but only some 15 nF @ 10 kV. Im planing to use rectified flybacks about 3 in paralel and a crt tube just lays waiting…….

That driver circuit is not great for optimum use of your coil. It make is difficult to find the optimum frequency and pusle width becasue you can’t adjust them independantly. You should find more info in the comments on the ignition coil driver page.

Hi , I build a empyrical tesla coil from scratch ( 555 driver, ignition coil (newer type,cm1t-210,works better than 2 old types in parrallel), 48x1n4007 full bridge rectifier, bottle caps, single static spark gap )and it works fine (15cm spark lenght). But I have a few problems, I can’t take pictures or movies because the sparks aren’t bright enough. I realized I needed more power from the ignition coil so I started messing with the driver frequencies (driver schematic at http://www.geocities.com/CapeCanaveral/Lab/5322/coildrv.htm)

Now it seems that for the optimal use of the ignition coil I will need lower driver frequencies, witch I achieved by inserting larger value potmeter (100K, replacing the one connected to +12vdc).

The problem now is that the one 2n3055 can’t take the current and fails after a few seconds of operating at the new lower frequencies. Can I use two or more 2n3055’s in parrallel like the driver on this site WITHOUT the bfy51 in front of them or are there other types of transistors that work also (bc548,bc338,bc328,bc547,bf422,..)

You can use some sort of calculator program, or find the formula and do some math. The numbers you get are always going to be different to the reality so be sure to allow for adjustments later.

If you can get a rough value from the formula you can then tune your coil by adjusting its tapping point on the primary coil, or changing the size of the topload.

Bigger topload reduces the frequency of the secondary circuit. Bigger capacitor or bigger inductance (more turns) reduced frequency of the primary circuit. The frequency of the primary and secondary circuits must match or be as close as possible.

Hi again, thanks for all your help and products so far, I was wondering how you work out what size capacitor you need and also the size of the topload. I think I have everything else I need and its just a case of setting it all up in a safe manner rather than on my test bed in my bedroom!!!

Well, I see a lot people interested in building a SSTC.

For those want to build one, you should visit Steve Ward’s and Richie Burnet’s site for both theory and practice.

http://www.stevehv.4hv.org/

http://www.richieburnett.co.uk/sstate2.html

SSTC is NOT that hard to build if one have some experiences with SMPS, it’s basically the same theory. However it did cost a lot if you want it to build a reliable one.

Anyway, RMC, I like your idea about Plasma Gun, it looks so neat.

cheers,

Bluemotion

I guess so. It is just a matter of power. 765 watts is probably just enough.

well, you see, it’s not an automotive ignition coil; it’s used to ignite the fuel in an oil-burning furnace, and it does have a continuous arc. So from what you are saying, it will probably work, am i right?

thanks again.

45mA at that voltage sounds like a lot for an ignition coil, thats 765 watts. I would assume that this rating is not for a continuous output. A continuous output of 765W should be enough, but if it is just short pulses only then it would not do. An NST, Pole Pig, or MOT is typically used for Telsa coils that large.

I recently aquired a 17kv, 45 milliamp Oil burner ignition coil. Would this alone be enough to power my 6 foot tesla coil (in the future)? Or would I need a couple of them in paralell?

Thank you for your info!

Neither resistance or capacitance alone can be used to increase the voltage of a source. Some thing dynamic (changing) is needed.

A resistor, capacitor or both will actually cause a voltage drop therfore reducing the voltage. I’m not sure where your misunderstanding came from.

how does adding resistance to high voltage increase it? i know capacitance does lol but i dont see how limiting current increase voltage were does the gain come from.

Your theory for measuring the voltage is fine, but you are not considering an important factor.

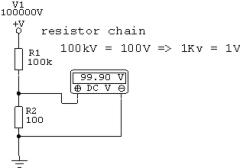

If you put 100kV across a resistance of 100k ohms the current would be 1 amp. There is no way your coil will output 1 amp at 100kV. This low resistance will effectively short the output of the coil causing its output voltage to drop considerably. To get an accurate measure of its voltage you would need have as little current as possible going through the resistors. A typical value would be in the 100’s of mega ohms.

So, like this:

Should I use 1W resistors?

Thank you very much, you really helped me.

Now I can get working.

You will need a string of resistors. Lots of high ohm ones together to form the equivalent of one very high ohm resistor. Plus a single lower valued one which you would measure the voltage across. You can learn more by following this link on voltage dividers.

Please choose a name and stick to it for your posts on this site. I makes it much easier for me to answer your questions.

I want to measure voltage from induction coil. I need a voltage divider – 2 resistors in series. Which are their resistance, power ratings and does one part must be grounded? Do I need only 2 or more resistors? Thx.

1) Find the 2n3055 datasheet for this info.

2) No, Not directly.

3) This circuit

Happy New Year

Hi! 1)How much voltage and current I need to normally switch 2n3055?

2) Can I connect 10W audio amplifier output to emitter and base of 2n3055 to make my TC play music?

3) Can you post how to use mosfet

instead 2n3055 (circuit)?

Many thanks and Happy New Year!

I no longer have the coil pictured here so I will have to give you approximate values.

Space between turns: <10mm. Maybe 8mm

Angle from ground plane: <45°. Maybe 35-40°

The angle is actually not very important. It has only a minor effect on coupling vs. just a flat coil.

Ok Thanks for help just one more question what is angle of primary coil and what is distance between turns ?

Cry_wolf,

Both. Use an EMI filter between the mains supply and the NST to protect your mains ring from radio frequency interference. You can also place RF chokes on the output of the NST if you want to stop RF getting to the NST. Use a saftey gap to prevent overvoltage where needed.

Markku,

40mm diameter

How thick is that plastic drainage pipe

from that diy tesla coil.

Oh and im sorry if my english aren`t wery good because i speak Finland.

I’m using a 7.5kv /30ma franceformer and i wanted to know what would be better-> a safety spark gap or frequency chokes.(i do not want to ruin this BRAND NEW N.S.T. just like my ignition coil circuit)

It is based on the Plasma gun

ok. One more question: do you think you could send me a schematic diagram of the circuit you described in post No. 2323?

I couldn’t say for sure because I don’t know the specs of your flybacks diodes. I’m afraid you will have to guess if you can’t find any data on your diodes. It is also possible that there is a current limiting resistor built into it already. Maybe you can find some info on CRT transformers on the net.

ok. I understand what you mean. But what value resistor should I use at the output?

der strom,

The output of a flyback is not necessarily DC. The flyback you described has a built in diode rectifier as DC is needed for a CRT screen.

You would need to protect the internal diodes from over current and voltage spikes. The diodes are probably not rated for much current so you would need a resistor on the output. This should then be used to charge a large capacitor. Then from this capacitor you would charge your TC capacitor via an inductor. The inductor allows DC to flow through easily but prevents the high frequency of the TC getting back to your flyback. This method is used in the DIY Plasma Gun.

You could try connecting like you suggest, but this might destroy the diodes in your flyback.

Daniel Kuriloff,

Anti-parallel is where there are two outputs of opposite phase and therefore opposite polarity ant any one time. If you wanted to use four coils you would need to use two pairs of coils in anti-parallel. A pair being two coils in parallel. This would give you about 2x the voltage and 2x the current relative to a single coil.

For a Jacobs ladder it will work better with more current because this is what increases the plasma temperature and allows it to draw out further. The voltage of your power supply will just determine the size of the gap where the arc restarts.

I want to maximize voltage output from four ignition coils for a Jacobs ladder using a 555 timer circuit feeding a high power MOSFET. How can four coils be connected in an antiparallel fashon to get this? Is this possible?

because the output of a flyback transformer is already DC, could I just hitch it up with a HV capacitor and a spark gap and use it with a small tesla coil?