A DIY Mini Pulse Jet Engine

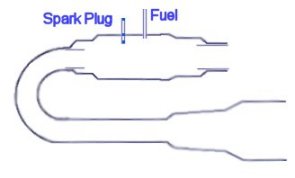

The valveless pulse jet engine or pulse detonation engine is the most simple type of jet and is therefore popular among hobbyists as a DIY project. it is often referred to as a ‘tuned pipe’ because its operation depends upon making the parts the right size and shape so that it fires, or resonates at the engines natural, fundamental frequency. This type of jet propulsion does not need any type of turbine, turbofan, or propeller, making it much less complex than a typical turbojet. In a turbojet the turbine or turbofan is used to compress the fuel/air mixture in the combustion chamber so that it is more efficient and powerful.

The valveless pulse jet engine or pulse detonation engine is the most simple type of jet and is therefore popular among hobbyists as a DIY project. it is often referred to as a ‘tuned pipe’ because its operation depends upon making the parts the right size and shape so that it fires, or resonates at the engines natural, fundamental frequency. This type of jet propulsion does not need any type of turbine, turbofan, or propeller, making it much less complex than a typical turbojet. In a turbojet the turbine or turbofan is used to compress the fuel/air mixture in the combustion chamber so that it is more efficient and powerful.

This jet engine has absolutely no moving parts and it relies on the simple shape of the combustion chamber and exhaust for it to function. The fuel to the jet is provided at a constant rate, but it is detonated in pulses. After each explosion there remains a lower pressure area inside the combustion chamber. This is immediately filled as air rushes back in and mixes with the fuel feed ready for detonation again.

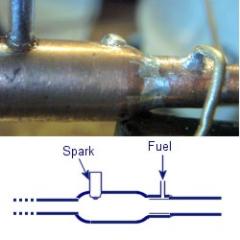

This example of a homemade jet engine is about as simple as it gets, but it could not be used for propulsion purposes because it is only safe to operate for a short time. The main body of the pulse jet engine is made from copper pipes and various adaptors. The combustion chamber is made from two copper adaptors that have been cut and soldered together. Copper is an excellent thermal conductor which helps to spread the heat throughout the jet, but solder melts very easily so if the jet engine were allowed to run for more than a few seconds this part could come apart. This was enough to demonstrate the principles of operation which is all this DIY jet engine was designed for. If you wanted a working model for providing thrust, it would be necessary to consider different materials as a running jet will get very hot.

These images show the basic ‘tuned pipe’ without the spark plug and gas supply. Tuning was achieved by altering the length and width of the parts used. This was quite simple as there are wide range of plumbing parts that will easily fit together.

These images show the basic ‘tuned pipe’ without the spark plug and gas supply. Tuning was achieved by altering the length and width of the parts used. This was quite simple as there are wide range of plumbing parts that will easily fit together.

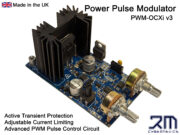

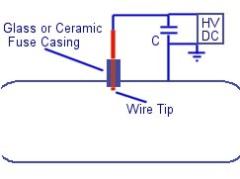

The fuel was provided from a cheap blow torch and was injected into the combustion chamber using fine brass tubes bought from a local hobby shop. This chamber also contained a tiny homemade spark plug. The spark rate could be controlled by varying the power to a HV capacitor connected in parallel with the spark plug.

The power supply for the tiny spark plug was made from a mini cold cathode PSU connected to a HV diode and capacitor. An alternative is to use an ignition coil and an ignition coil driver circuit.

The spark plug its self was just a single wire inside a small glass fuse. This wire was connected to one capacitor terminal (live) and the body of the jet engine was connected to the other terminal (earth). The spark would jump from the tip of the wire to the inside of the combustion chamber to ignite the fuel mixture.

The spark plug its self was just a single wire inside a small glass fuse. This wire was connected to one capacitor terminal (live) and the body of the jet engine was connected to the other terminal (earth). The spark would jump from the tip of the wire to the inside of the combustion chamber to ignite the fuel mixture.

The simple design and adjustability of this jet means that a wide variety of fuels can be used. The most common fuel used is kerosene and propane, but common lighter gas will work for this basic demonstration. Click here for More information on Jet Engines.

They are typically made from steel. They are typically not used for vertical liftoff as they are not powerful enough.

What material would you recommend for the engine, how big would it have to be for it to achieve vertical lift off with 150 lb, and how much thrust would it have to provide for 150 lb to get off the ground?

if that pic didnt show up right, here is another

I’m gonna use a pulse jet for a rocket im designing. the rocket is gonna be about 10 12 feet tall, maybe 5 inches wide. this is the simple design i want, can you show me some better detail on something that will work for the engine.

/\

_|_ / \ _|_ vents and fans

\ \/ \/ /

\/ | | \/

/__| |__\

| | | |

| | | |

| | | |

| | | |

| | | |

| / \ |

| |

| |

jet

obviously not completely to proportion. i can figure out fuel tanks. i can figure out putting a high powered fan in the top of it to get some start up for launch. just need help to put something like the engine in the picture at the top into a rocket. that will weigh no more than 20 lbs. so 50+ lbs would be preferred but enough to keep it moving without falling

i am 17 and from australia, and i was wondering if anyone had any idea how to make a turbo ramjet… at say 1:15 scale.

this is all part of an experiment i am about to start, if your wondering…

Hi This is not my Rocket but I hope to build one like it, it is a model copy of a lockheed design I see above the dicussion was to make the curve around the tail of the rocket more sweeping yet this has a very square shaped tail would it change the reaction much to keep the same size but make the tail arc say around a mandrel that is round thanks H.

hi my name is joseph i want a jet like the one int the pic those anyone have one and is u do can you tell me how much it is 10q

1. Steel

2,3. Yes. The dimensions of the pipe have to fit with the ferocity of the explosions. You’ll have to figure out those dimentions yourself. You’ll find some good info from others above.

Hello, i’m new here, my name is alexander as u can see and i’m 17 years old. One of my dreams is to make an RC car powered with two pulse jet engines and i hope that u guys will help me to make my dream come true :).

1st question: Which material should i use to make pipes for this engine?

2nd question: Is there any proportions of thickness/lenght of pipes?

3rd: How big and long it have to be that the RC car can go about 60kmh (24mph) or a bit faster, remember that i would place a two of them and everything shouldn’t be heavier than 5kg?

Sry for bad english, if it is 🙂

The expanding air moves out of both ends of the pipe so they face the same direction to maximize thrust.

hey.. was just wonderning. is it absolutely necessary for the tube to be U-shaped ..wont the air intake facing forwards have much more effect?..like when youre moving

This is for Scotty

Hey If you are working with fusion you better watch your ass that is verry unstable engineering your risking your life 100 fold of a pulse jet if your core cracks even if its a hair line!

After looking some more, it may also be a combustion heater manufactured by Bell helicopter. An option for a bleed air heater is also possible.

Chris,

That looks like a reaction thruster for some kind of rocket. (I.E. That is a real rocket motor!)

Hi im new here ,,and can some one please tell me what this is ..made by Bell

Scotty, you seem like you’ve done your research, thats some good work. When you do go looking at ‘girls’ remember they can take up a lot of time. If you cant keep the one you get, much time is to be lost looking for a new one (there aren’t many around for your type:( this will impact on your hobby time. So treat the one you find well.

That all looks pretty cool, but I think you guys should step it up a notch. A few years ago I decided to build a fusion reactor in my garage, and after success with that I got into building jet engines. A few more years of that, and I just finished building my first homemade warp drive capable of interstellar travel. It’s pretty chill. It only cost me $57 in parts and a fair amount of time scavenging (very hard to find a good source of antimatter) but all the hard work paid off. Maybe next I’ll try finding out what this “girl” thing people keep talking about is. Keep up the good work!

Hi all. I have made a turbo jet and some pulse jets. The turbo jet was impressive but was too heavy, and complicated (needs constant oil supply and is tricky to start). My first pulsejet was easy to start (once all the pipe lengths were right), light weight, simple and made heaps more thrust than the turbojet with the same fuel supply. I’m currently building a huge pulse jet to put on a cart, the main tail pipe is 7 ft long. It will run on LPG then when its hot to get more power i will be able to add varying amounts of diesel vapour. Has anyone tried running these on dual fuel?

Just letting some onlooker know…

I have built and sucsessfuly ran two Gr-1’s Four Gr-5 (turbo shaft) three pulse jet (one 15 feet 184 lbs of thrust)(two 6 foot) and a pen jet (realy cool “but realy hot”)

Contack me @ Christopherkoen@yahoo.com

Hope I can help.

hi,

I am interested to design a valveless pulsejet engine of 0.5kg thrust can u suggest a method to estimate geomery of that engine

Well thank u bizzare. I think that I am going to do it. It shouldnt be that hard, just some spot welding and a home made turbo.

On the contary though, a bigger tank with more volume + water would take longer to heat up. So lets say i have a heat source of x amount. It would take x twice as long to heat up 2 gallons of water then 1 gallon, also the water would evaporate twice as slow – thus less pressure. The less volume and water = more pressure – if that makes sence.

I didnt know about the water in gas form to water in liqued form ratio though. Thats actualy sounds pretty promissing, 1 / 220,000.

Im not sure, but when water is boiled it will produce 22000 times bigger amount of steam. So water to steam is 1 to 22000. But to run turbo charger, on high rpm, you need really huge amount of high pressured steam. So it means massive tank, massive tank walls, some kind of water pump (you cant wait until 50 litres of water will be boiled) etc…

But you can try it… try is for free …almost :D:D:D

I have an idea for making a pulse jet. What if the combustion chamber on a pulse jet is completely surounded or enclosed by another cylnder filled half way with water. When the engine heats up, it would heat up the water to boiling temperature creating a masive amount of pressure. This enclosed container would be conected to a turbo charger where the exhaust would connect. The other side of the turbo ( the compressor) would ram cold air in to the intake of the jet engine.

Also the comustion chamber is cooled to a lower temperature from the outside container, therefore more oxygen is alowed in during the intake cycle at a higher density. Of course it would only work untill the water was boiled out, but would it work in theory or em I a retard ?

I see a lot of experimenting with pulse/det engines here but has anyone here actually done a mathematical model of it before they make them? Id like to see the math (being a mathematician)

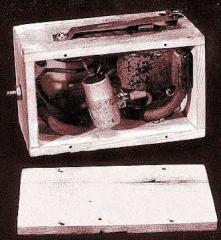

Just thought I would throw this on here for the hell of it total engine cost $110

i’m making my own airbus using sticks.. on my own creativity.. the body of the airbus is about 42inches long.. and been looking for the suitable engine for this.. any suggestions??

Thanks..

I have never built any jet beyond a very weak pulse jet in my chemistry/physics class. However, we experimented with various fuels, such as hydrogen, propane/butane, and various other mixes. We also tried distilled isopropyl alcohol, which worked sortof well provided the jet was fed with a supply of vaporized alcohol

In Theory??

Usage of household kerosene as a fuel .. Pressurise the fuel tank. Preheat the fuel by coiling the fuel line around the exhaust to gasify the liquid kerosene. Allow the resultant gas to enter the combustion chamber through a fine nozzle.

i am looking to make a rocket nothing fancy just something with enough thrust 2 lift a 2 1/2 stome weight off the ground can you tell me what i need to make it and how

Hey guys I looking to build a pulsejet for my gocart all I have is a mig welder and some basic tools where should I start?

how heavy shold the engine be

hey people, fair play to you all for building these beasts! as a recovery op, i can get my hands on most parts, scrap metal, turbo’s, plugs and coils. am definatley going to give it a go, will post some pics when i make a start. once again, hats off to you!

Great site. As a retired Mech Eng. all you younger people give me hope for the future. Start hanging around a local machine shop (one/two man shop) if you can. Mistakes and failures are just part of the fun. Try to BE SAFE as pain hurts and death is forever.

Hey Gene, refering to your post way back in 2006 about 13 being young. I’m 13, and my friend and I have built 3 go cart, hundreds of rockets, messed with hundreds of fireworks, flown “modified” rc gas planes :), and tons of other explosive things. I think we can definetly build a jet.

Thanks,

Spam

I’m starting to make a no weld pulse jet. I found the idea on the net by a guy named Bruce Simpson. The problem is that the info he provided is incomplete, he hasen’t updated the site yet. I’ve got the combustion chamber, (stainless thermos bottle) I’ve got the exaust pipe, I’ve even made the reed valve plate(1/4″ aluminium plate w/8 convergent holes 1/2″-.47″. What I don’t have is the reeds, the fuel type and delivery system, the intake venturi(I have no idea what to use. Keep in mind that I’m trying to use readily avalible materials, And as little high teck tools as posible ie. welder, leathe, mill.I don’t have these resorces.) and th ignition system. I just want it to work. It doesen’t have to push anything, it’s going to be static. Any info you can give would be very helpful. How well would Ti. work for reeds? Can a carborator from a motor cycle be used as a fuel and veturi sorce?

I’ll take “any” info you guys have.

Thanks; Keith

Do not even try to build anything remotely similar to a jet engine. Get your parents to make it for you. It is extremely dangerous to play with fire or flammable things. Don’t do it!

hey guys i am 10 years old and want to build a mini jet engine for my mini jet plane but i dont want to kill myself .i dont want this way .can u tell me another way?

Hi. Would a spark plug set for a motorbike or car do for a jet engine? Just wondered. I only got a far as ducted fan or propeller powered model cars and planes. I am jealous that there are 12-15 year olds who have made their very own jet turbines. Where would I get hold of the turbine blades and axle that is in the picture further up the page? I did the pump a lighter into a 2 litre bottle party trick and it flew across the kitchen table. Was dead funny and safe[ish] but its not advisable..I will be in touch.

can you put photos of the interior, or diagrams?

hey were do u guys get the meatal turbines???

Another no weld jet engine that looks really promising. http://aardvark.co.nz/pjet/noweld.shtml

For anyone who wants build a jet engine cheap (bacily no thrust but cool effects).I made one out of 2 old computer fans,old meatal pipe (i got one from lowes 15 $), and a spark plug.

im only 13 but this works really well for effects or braging rights.for fuel i used a 95% alchohal trate but u should use a lower grade (kerosene).And injcet the fuel in a mist.(sry about no pictures my computer wouldnt downlaod them??? have fun 😀

hey lucas,

to get a jet engine to power a go kart u cant glue,paste,tape,etc. but on this site ifound jet engine plans that use muffler sealant http://aardvark.co.nz/pjet/noweld_pulsejet.shtml

hope fully this helps 😀

I’m sure you don’t want to put a micro jet in a Go-Kart

im trying to build a no-weld pulse jet for cheap. it is going on my go-cart. will it have enough power? do you know what i will need to make it?

hello guys, i’m kenneth, recently i was browsing throught jet engines which is very interesting to learn an work on. after reading all our comments and question that u all have posted,i’m shocked that even kid can make their own jet turbines. i’m really amazed.i was thinking of making my own micro turbine engine but i have no idea where to start.i wish u all can help me and teach me how to start making my own micro tubine engine.please help…i’m really interested..

Would it be possible to cool the exhaust and increase thrust by injecting a water spray at some point, such that the water would absorb heat, and at the same time produce steam and greater pressure and exhaust velocity?

Rainer, what kind of turbocharger is pictured? I’m interested in constructing one with fiol bearings.————Thanks

dear spj rmc knows a lot more than me about jets but i m designing a new valve system for the valved pulse jet. it kinda looks like the curved bottom of a deoterant can and it slids on a action bolt. ill make a video on it soon.

somebody can send me a detail document about minijet? my email here “ad28888@yahoo.com”

where can you find cheep and easy (bacic tools)

to build pulse jet plans/blueprints

You can make a simpler pulsejet out of a 6 inch long half inch copper pipe (open at both ends) with a 1/8″ hole drilled at 2 inches in from an end. Just feed propane into that side hole from 1/2 inch away with a handheld torch that’s had its flameholder screwed off. Light either end of the copper pipe with a Bic and adjust the orientation of the gasflow until the bzzzz maintains. So easy!

You guys seem to be working on products that also apply to renewable energy for gas turbines from 200 kw up to 1 mw gap in market for small scale generation . with a boiler bolted to the waste heat flare and a steam turbine on the end of it . if any of you guys can come up with the goods I will find the markets in europe and asia

Phil

I realized I can’t read or spell either. I just realized the dates….:) Justin has probable put together the next age jet engine by now. Pretty sad, but it usually takes me a year to catch up these days. So I guess I am on schedule.

***JUSTIN*** JUSTIN, I am by no means even a novice at what you guys are doing here. However I have been reading about your problems of attaching things to you pulse/ram jet(?) and that soldier or welds may not work. Being more at home with HIGH performance racing engines, have you thought about using a TAP & DIE, THEN SCREWING THE ITEM ON? I have also secured items after this procedure with a two part playdo type epoxy material whihc hardesn to a ROCK!! I have used it to seal a place which temps reach 900+ degrees and it still remaind as hard as a rock. You can also use a high temp sealer if the tap & die solution works. Again, I KNOW NOTHING about what you guys or doing or how I arrived here? No I take that back, I was looking for a jet engine(used). It makes me happy to see people 13-14year olds learning about this stuff. Hopefully it will be used for peaceful purposes by 99.99% percent of the people who do learn about it….:)

Hi people,to those of you who are building small turbine jet engine ,I have hundreds of used tubine and compressor for about $3-$10 a pair set,and oh I build small turbin jet engine, and those to are for sale for about $150-$1000, I dont have any cooling system so I make my own out of pc cpu liquid cooling unit,it’s small and work great to cool down hot bearings, well I hope this help ,need more help just post for me, I’ll check in daily

Cool site 🙂 I have built a vane type pulsejet before and a turbocharger turbine. Think I will try one of these vaneless types. 🙂

First joe you should tell what kind of engine it is…

no weld? there’s no such think like that, if you want to build a quality jet engine you must weld it, if you don’t there are lots of risks incluiding: fuel escaping, folgs, and even explosion of high pression made inside. This is not to play, a project like this even a mini one must be welded

Go to the link i’ve gave to alan about how to make a turbine jet engine i don’t know if it will help but you can see

Hi everybody I have built my jet engine the only problem is it starts but when I add the fuel it quits

i am building a turbine engine and i am having trouble with the combustion chamber does any one have plans for a NO WELD turbine engine

yes but you must considerate not only the weight of the bike but too your weight, if your mounting the bike!!!

I think you misunderstand. I was talking about a higher-end bicycle; I have an aluminum hardtail I could use. It weights less than 30lbs, which I would think is much less than a go-kart, and the wheels are semi-frictionless. 10lbs of thrust could probably get it going fairly quick…..

hey andrew can you help me with this project please? i’ve been making a air compressed generator, that works like this, the air enters in the cylinder(the air comes from a external compressor), i’ve alreaddy made, and makes the other cylinder move down, making the generator generate voltage, but i don’t know really how(i’ve alreaddy got a very nice way to, but i want your opinion first) to make the air come out off the cylinder, like a internal explosion engine, comes inside and has to go outside, can you send me your plans of what you have alreaddy made? thanks

I’ve got 3 welders, some of them are cheap others not, you have to choice, yes a bike would be more less heavier then a wood car, you have to see the bike wheigh and calculate how macu lbs you need to make the bike move, in a determined time, with a determined velocity, for that i’ll soon give you a link for you to download the thrust calculator for, to help you with that, i can’ give it to you now because i’m not in my PC anyway i’ll soon send you the link

Small wood car? Yes, I can see why… you’d have to pay a small fortune to get bearings good enough to go fast on 10 lbs.

But…

What about a bicycle, with $300 wheel hubs and road slicks? I’ve got a bike that one of these could be mounted on…. the way I see it, I could build the engine around the bike. And anyways, I’m going to be limited to what parts I can get from a junkyard; I don’t have a welder and my budget is somewhere around 50 bucks.

yes to appear like a toy but if you want a good power you need at least 20 lbs to move a small wood car

Thanks Cliff; I don’t know why I didn’t go to instructables in the first place…. I’m going to have to configure mine to give about 10 lbs of thrust, minumum… is that practical?

Alan the Great go to the link i’ve gave to you in one of my last comments there you have how to make a turbine jet engine, i’ve alreaddy made and the instructions are correct

according to xe.com, 19.99 GBP is equivalent to 29.37 EUR. The currency is converted automatically by paypal when you use the online store.

hey RMCybernetics can you tell me the price of 19.99 £ in euros please? i don’t know and i would like to know to buy that high voltage spark coil, and there’s only one left i don’t see probability’s of me to buy it… please tell the price if you don’t mind thanks

Never mind previous messages; I’ve finally decided that I’m building a turbojet. I’d still like to know of some knowledgeable web sites, though…

Can’t find an old turbo, so I’m going to go with a lockwood. If I can get it up to 10lbs of thrust, I’ll mount it on a bike….

And what you said about jet engines were so easy its very relative because pulse jets are very easy to understand how they work but turbine, fan, shaft, and turbo prop aren’t so easy like you think, you must have more theory then practice to make them believe me

Yes you can serch on this site, its a URL directed to what you want. I’ve alreaddy donne this turbine jet engine for me its the easiest one turbine

Wow, I didn’t realize that jet engines were so easy… I’ve apparently built a single cycle pulsejet engine (read:potato cannon) without even knowing it!

I do have a bit of mechanical know-how, so I’m going to try a turbo engine for my next project. Does anyone know any good web sites on building a jet engine out of an old turbo?

the dependent compressors don’t have any moving parts, but let me tell you the mini pulse jet engine as a small aluminium turbine homemade inside, with a few ours of experementing the engine i’ve decided to put it in to optimise the incoming of the power pulse and to use more the thrust, and it worked the engine got up to 0.5 HP(HOURSE POWER) i’ve calculated with a force engine acelerator that my grandfather had to calculate the HP of the engines, if you want this info for anything about that mini jet engine you have it

I’ve been asking to mechanicals for liquide fuel injectors but i’m having some problems on fiding them please can any one help me? thanks

i’ve wrote wrong sorry i’ve said that i’ve used the bigger DC to power a wood car with me in it, i’m today beggining my constrution turbine engine with a land rover water pump turbine (we have to be creative everything works we just have to make to) and the making of the apropried flame and combustion chamber of the turbine engine

they all work well, i’ve alreaddy used that bigger DC jet engine to power a wood car i’ve made with in it

the mini DC and the mini pulse jet engine are only 22 cm long

that small tube that comes off from the mini pulse jet engine is the gas tube, comment please and thanks

onother foto of my mini pulse

this is my mini pulse jet engine

this is my mini DC

this is the DC, i don’t know if these images got to mutch small….

i’ll put those jet engine images today in the site so that you RMCybernetics can give me some ideas thanks

Thank you soo much man, i really din’t knew how to make one, i’m thinking on buying your High Voltage Spark Coil i’m needing… yes and how can i make a part of the RMCybernetics group? when i’m found that DIY were working on lots of thinks that i’ve loved to make i’d like to make a part of the group (i know i can’t lol but i would like) i really like this site, always loved high voltage electricity, plasma, propulsion systems and stars…. there’s only onother think that i love that represents force, like all off this thinks i’ve talked about that do to me, but isn’t mensioned here… doens’t matter i love this site please can you tell me if i can make a part of the group? the DIY or something like that?

The glass fuse is dissasembled so that all you have left is a small glass tube.

The glass is then inserted into a hole in the combustion chamber so that about 2/3 of its length remains outside.

This glass tube serves as an insulator so that a thick wire or metal rod can be inserted without it touching the metal body of the jet.

When the power is on, the spark jums from the tip of the metal rod to the nearest part of the jet engine casing.

It is glass, so it is fragile and will melt if your jet gets hot enough.

To convert 12V DC to a high voltage for a spark you will need an inverter of some sort. This project used a cold cathode tube power supply a HV diode and a small HV capacitor

A better method would be to use a proper ignition coil and a driver circuit.

Does it get destroyed with the combustion? it looks it is very fragile…. i’ve got 3 engines and i’ve got no sparkplug that fixes with them… i need a small like this one but i don’t understand how it works… if you don’t mind explain me like i was a donkey lol i’m really not understanding how it works… ohhh and yes what kind of material you use to amply the voltage of a regular battery (12v) to 1 Kv? please thanks … you’re my master lol

I’m sorry, i’m not really understanding how it works, its a fuse but should i brouk the glass so the sparkplug makes effect? Please can you explan my better , thanks

See the post dated Tuesday, 29th August 2006 1:23am for the spark plug info. Voltage was about 1kV, but voltage above that would be ok too.

Hey RMCybernetics can you tell i was that tiny sparplug made for that mini pulse jet engine? What intensity of voltage is needed to spark that spark plug? and how and of what was it made?

And i’ve built this air cool pulse jet, well we can’t see the coooling system but it is there, and i’ve built a 15 cm compr. pulse jet so small that it can fit in your hand easly. I’ll place the foto here when i take it it’s very cool that tiny pulse engine. The next project i’m going to make is a turbine jet engine. With internal compressor, ohh and yes i’ve called to both of the 2 engines i’ve mencioned before DCC (Dependent Compressor & Combustion) or like the name says it does not have an internal comporessor and the combustion is not automatic in the bigining or like that it does not have any sparkplug no spark the mixture of fuel. But one of this days i’m gonna build a crazy turbine and internel compressor jet engine, one of the types of most complex jet engine types!!!

To make a spark plug spark you need at least 5000 vlt to 20000 vlt depending of the sparkplug and the fuel your using. For that you need of a coil to over-intense the 12 v you have from a regular car battery to 5000 vlt or more

It’s usually at least a few thousand volts. As mentioned in the article, you can use a PSU for cold cathode light.

but how many volts do i need for the power supply

Very interesting site guys!

I have spent nearly 2 hrs. looking, reading etc. especially liked the links to both the “maggy muggs” and the ” jet boat” projects….nice to see such creativity…just don’t blow your collective A$$ up 😉

Rochester, New York.

The capacitor is just a small creamic type rated for a few kV. This capacitor is charged using a small high voltage power supply.

what capacitor do i use for the sparks

because you need a capacitor to give a pulse

i need help so what capacitor?

PLEASE HELP

Hi, Guys. I was just passing by, and saw a question about manufacturing a ‘flared’ tail pipe. The easiest way (which i’ve used for airbox bell mouths, on motorcycle engines)is to have a carrot shaped die made up, then press it through a suitable ID thin wall mild tube, with a hydraulic press. Due to the diifficulty in rolling a tube with a small diameter , or machining up a thin wall cone, it’s a heap easier to just stretch a tube to the correct dimensions. By pressing the flare, too, you don’t get any weld seams, to disrupt the air flow. To make the die, whip it up out of wax, and take it to a ferrous foundry. They’ll cast it for a couple of bucks, and off you go !!!!

This effect is caused by the fuel/air mix inside combusting and expanding. The Pressure buildup inside will force the gasses out of the hole.

This is similar to the pulse jet operation, but the fuel/air mix needs to be better so that it burns much faster (i.e. explodes)

Please be careful, and dont try making jets with fuel and plastic bottles.

hi everybody,i have always been interested in rockets and jet engines and stuff,but i was playin with one of those big blue water jug things one day and i sprayed some airosol into the top and put a small hole on the side of the jug,a huge flame shot out of it …is this anything like a pulse jet engine thingy??? do u think if i supplied it with a constant supply of air and fuels it would just keep thrusting?

The U-bend is only important for making the thrust go in one direction.

why is it so important to have a curve in he pipe?

I have made one of the simplest pluse jet ever. I made it out of a tin can with kerosene in it then i lit it then got the oxy and just blew oxygen into in at full blast same. same result as a pulse jet

hey justen my names dane and im 12 and im just getting into jet engines can u please send me plans and all the fabrics yourll need to make one and what type off gas so ill look forward to seeing what you can send to me but make sure there not to hard to make and if anyone else wants to send me something you can (bob_bollen@hotmail.com)

Awosome, this is very good to know how cann i built a turbo engine, great.

Unfortunatley my jet is too small for welding, as I currently only have an arc welder available.

It does sound like you are on the right track, let us know how you progress with it.

thanx but you can easily make a tail pipe out of a bigger pipe and cutting out a triangle shape squeezing it and welding it together. thats exsactly what my jet sounds like also so would this mean that im on the right track

Yes the smaller ones are much harder to make work. With a large pulse jet you can adjust the fuel input to alter the throttle, but the smaller the jet, the smaller the throttle range you will have available. This means that for a tiny jet the fuel rate needs to be just right in order for it to work.

This can be very difficult in practice as there are many other factors (such as atmospheric pressure!) that can effect the flow of fuel.

The resonating sound from a pulsing jet comes from the resonant frequency of the air space inside. It ‘s like when you blow across the top of a bottle you hear a note that depends upon the volume of air inside. Less air = higher frequency. These tiny jets will have a notabley high tone.

Yes, I think a flared tail pipe should help the fuel mixture to reignite itself as it helps contain some of the hot exauhst. This hot exauhs must be sucked back in to detonate the fuel.

I’m still waiting for my tailpipe to be made, but it looks like its not coming. It looks like I may have to pay for it! 🙂

also would flaring out the tail pipe increase the chance of it working

hey its me again i built this little pulse jet and it buzzes very loud when oxide is put in with the propane fuel mix but it dose not sustain are little jet like this normally hard to start and get working on propane plus the tail pipe got red hot. it sound like a metal pipe ring like when you hit metal and it rings is that what it should sound like?

I think the buzz box is just an autotransformer (ignition coil) and a driver circuit.

You can see a few examples of circuits on the ignition coil drver page or the pulse controller page.

My name is andrew and I am 15. My hobbies are making small engines “High performance” and building “Steam” engines that run on compressed air(not c02). I have a supercharged Honda 5.0 HP and other odd stuff. I am able to build such things because I have a machine shop. I am interested in building a mini “STEAM” type engine, but make it run on fuel(Internal Combustion). However I need to create a spark?

These are a few things I have that are in working order or never used :

-Briggs coil (Magneto)

-Chainsaw coil (Magneto)

-Chainsaw condenser

-Harley Davidson Condenser (Golf Cart)

many more…

I have heard of a “Buzz Box” such as the one in the picture, and dont understand how to wire it or something like it.

I have many more things to use AND the tools. Please tell me any ideas,plans, drawings, etc.

Thanks, Andrew.

How do i calculate the max rpm on my new turbine?

It is more than 80 000rpm.

this is my next turbine project , without the turbo casing, im using ceramic bearings.

This is one of the hardest bits to get for the pulse jet. I’m still waiting for a piece to be specially machined for me, but I will not know if its works until I try it out.

With larger pulsejets people often use a rolled sheet of steel that is welded at the edges to make your tapered section. This is not always practical though in smaller models.

RMC . How do you make the flare at the end of the tail pipe ?

Rainer,

TURBO LEAKING OIL = PERFECT FOR GAS TURBINE

My turbo leaks oil from both the compressor and the turbine and it runs perfectly. I should mention that it is safe to start as long as the comp and turbine wheels don’t touch their housings.

helloooooo everybody, this turbo turbine has dameged oil bearings, because the turbo is full of dirt and i have over presurized the iol pressure. it works but it leaks oil. is it safe or unsafe to start?

Hey Jim,

A bull bar would be ok but only if it is steel. Most are aluminium so you might have difficulty welding it. Aluminium also has terrible heat handling capabilities it will expand, crack and deform under the high operating temps of a pulse jet. Glad to be of any help.

Im buiding a pulse jet also but to start off with the tail and inlet pipes are allbigger than normal so i can throught trial and error work out the right frequency Htz.Gene would this be a good way to stat off? Also a good bent pipe would be the bullbar off a car wouldnt it ?

I am needing a quickie jet engine, incidental to a high voltage project.

Has anyone played with using parts taken from brass musical instuments … im thinking slide trombone … as an engine chassis ? The even taper of the horn pipe, up to a bell, should make an awesome coupling for air pressures and provide lots of surface area for thrust. The finely machined tuning slides on these instuments may also be great for adjusting your effective pressure pulse frequency (pipe resonance) along with your fuel injector flow, to extend throttle range.

Any ideas or suggestions, as far as :

1) brass engine chassis

2) high voltage present on engine frame

3) intake / exhaust pointing downwards

any or all comments welcome … thanx

Hi guys,

Look i don’t know if its my place here, and i certianly don’t want to discourage anyone but don’t you think 13 – 14 years old is a bit young to start playing with volatile fuels in confined spaces? I mean, obvious dangers aside, have you consided the skill and tools requied for such an undertaking? My advice start with something easy, learn to fix your bike, figuring out how a lighter works would also be a good start, after you’ve done that then you can build a “jet engine” – you’re 14 right? Then there is plenty of time.

Hi Adam, Its hard to say which type is easyest really. The pulse jet is incredibly simple as its pretty much just a pipe, but as you can probably see from the posts here, they can be difficult to get to run, especially the smaller ones.

Making jet engines at home is very dangerous so you should think carefully about what you put together, and make sure you fire it up outside your house. Pulse jets often ‘flame out’ which is where a big fireball shoots out due to a buildup of fuel, or problems starting, so you must keep your distance from them.

If you want to build one, make saftey your number 1 priority.

hello i’m Adam and i’m 14 years old i like jet engines and i’d want to make one. Which type of jet engine do you think would be the easiest to build for a beginner. I would like a very low, low, low powered one so i don’t mess up and blow my house to pieces.

Hi RMC,

In regard to the fuel to use i’d recommend lpg first (because it is the cheapest and easiset to get). Don’t even bother with hydrogen – you’ll probably never make enough. If you need a really volatile fuel then Acetylene is your best bet like Joe also recommends. Hope i was of assistance.

The dimensions are roughly based on the dimensions of this pulse jet

but scaled down. The scale is as close as I could get with the tubing I have laying around. The relative outer diameters of the pipes im using are:

15mm combustion chamber made from a section of standard copper pipe. Slits were cut in the ends so that the could be squeezed to make fittings for smaller pipes.

8mm air intake.

6mm Tailpipe.

2mm fuel pipe.

I don’t know how wide the tail pipe will taper to yet, but it will just depend upon what I can get.

The fuel is injected into a collar around the air intake which may or may not help with the mixing of the fuel and air. The flow of the fuel should also induce air to flow in, allthough I think the low fuel pressure will mean that it doesn’t make much difference.

The fuel pipe is brass, so I’ve bent it around so that it also acts as a stand for the jet

PS: Here’s some data that may be useful to you guys. The upper and lower limits for the percentage of fuel in air to produce an explosion.

Propane

HI – 9.5

LO – 2.2

Butane

HI – 8.5

LO – 1.9

I got these numbers from a forensic report about a fire in a building. If anyone has figures for other fuels please post.

Gene:

I’ve not used LPG before, I’ll probably try a few different fuels if I can’t make enough H2.

Here’s some more useful numbers. This shows the relative calorific values (in MJ/kg-1) of various fuels (data mostly from here);

Ethanol – 30

Methanol – 23

Diesel – 46

Petrol – 47

Kerosine – 47

Butane – 49.5

Propane – 50

Methane – 55.5

Hydrogen – 141.8

could explain your design in more deatail

Nope not yet, needs the tailpipe finishing. Its also needs a fuel supply.

dose she work

Its just another pulsejet based on the common Lockwood Hiller design. This pic show how it stands so far.

Notice the massivley over sized spark plug is the same as is used in the main jet example on this page. The graph paper in the background is 5mm to give you an idea of scale. The final dimensions may change so theres no point in posting exact details yet.

I’m wating to get the conical tailpipe made and I also excpect I’ll need a source of hydrogen such as an electrolyser.

what type of jet is it?

and design wise.

can u if it runs paste the plans or meassurements?

Acceleatien would also be a good source of fule.

If by “other pages” you mean pages showing common Lockwood Hiller type pulse jets, I would say allmost.

This one is very small in comparison and can be very difficult to get to run using just butane or propane. With some persistance it can be made to resonate at “the right sonic frequency”.

A major drawback of this jet is that by the time it gets started it is allready quite hot, so the gas needs to be cut as soon as it begins to buzz.

Even if the solder joints did not melt, I don’t think that this jet would self run contuously for any useable length of time as it was vey difficult to get it to buzz without misfiring.

With very small pulsejets it is often neccesary to use a more volitile fuel such as hydrogen. I’ve just been making a very tiny one, that will probably need Hydrogen fuel. I’ll post it if I get it working.

dose your pulse ejt have the ability to work like the pulse jets seen on other pages.

by this imean dose it create the right sonic frequency.if so can you paste your dinamics

This site has a wide variety of valveless pulse jet designs. Some were successfull and others were not. There are a couple of step by step construction examples too.

Scroll past the stuff a the top to the silhouettes showing different designs. A few will have links below for more details.

Just a comment here. I believe that these types of pulse jet engines that you are working on were used during the second world war to propel the V-1 “flying bombs” that Germany used on south-east England towards the end of the war. They were launched from occupied Europe and flew with a rudimentary guidance system which basically kept them going in a straight line. They had wings like an aeroplane and had a range of 150 miles or so. I’m not sure if any reached London but the buzzing sound they made gave them the name “Buzzbombs” or “Doodlebugs”. The sound of these inspired panic, especially if you heard the sound stop suddenly – then you know a 1000 lb bomb was about to drop nearby.

i have the same problem.

my hole jet dosent work.

i think this is due to the fact that the comustion chameber is too small.

Yes that could be the problem. Its is important to get the ratio of the pipe sizes correct for it to run well. If it is your first jet then it might be good to make some parts interchangable while you learn how it performs. When you are happy with the sizes you could then weld together a finished version.

When making a pulsejet you will need to ‘get a feel’ for how different design aspects affect performance.

This page shows another DIY Pulse Jet Engine and shows the dimensions used for the pipes. It has a squareish U-bend with a relativle narrow diameter.

my pulse jet has the right size pipes but like the picture at the top i welded mine very similar.

im worried the guy at the top will have the same problem. the tail pipe might be restricting air gas flow down the curve. could this be the problem? please help me rmc.

It shouldn’t be too difficult. It is possible that as you increase the gas there is not enough air getting in to allow it to detonate. It is possibly because of the ratio between the size of the combustion chamber and the tailpipes. Also if your Jet is small it will only have limited throttle range in comparison to a larger one. A larger Jet will also need something to inject the fuel better so that it mixes with the air.

Here are a few links that may help you figure out your problem. This page, Troublshooting PulseJets, is for the valved type but most of the principles still apply. You can also get a range of PulseJet Blueprints, but the preview links on that site seem to be broken, the download ones are ok though.

are pulse jets hard to start.

mine starts for a while { couple of seconds} on low pressure and when i add gas it cuts out.

what should i do rmc?

I’m sure you have already been there, check out Nye Thermodynamics website. They built a jet type device. I don’t know if you can really call it an engine. But by the photos included,you can see “mach diamonds” in the exhaust flame. Which by what I’ve read happens when the exhaust moves faster than the speed sound ? I’m not really sure! But they claim it has no mechanical moving parts….http://www.gas-turbines.com/hornet.htm.

thats the page where that project is located.

This may not make it on this site..but I believe that site maybe relevant to your viewers. If not sorry for even stopping by…….Be cool..keep it hot!!!!

Hi Justin,

Unfortunately thats were my help runs out because i’ve never built a valveless pusejet before (Although plan to in the near future). All I can suggest is trail and error these things never work to an exact calculation especially with homemade stuff, i’m sure with a bit of mucking around with the engines different dimensions you’ll get it to run. On the safety side can I recommend that if you cannot achieve ignition with a small amount of gas do not solve the problem with more gas – you know what will happen there! Just take your time playing with the amount of air you put into the engine when starting an pay attention to the ignition system (thats what gave me the most trouble on my engine). Anyway have fun.

BTW i’m sure you’ve been to this site but just in case –

http://www.aardvark.co.nz/pjet/mylockwood.shtml

Sorry bill, i missed that one.

I couldn’t say what the best way is, but the method used for the jet on this page was to feed in the gas via some thin brass tubing that was inserted through a hole in the combustion chamber

i reapeat, what is the best way to connect the fuel to the jet? please answer!

Justin,

All I can say is HOLY CRAP!, dude that was fast considering the amount of work you put in. I’m 19 and at you age i could’nt even weld, that should work very nicely. Might pay to finish it off with the ajustable exhuast, if the engine dosn’t run already that is. Good luck and happy i could help.

Hi Justin,

The easiest way i can think of is to use what i used for my engine – two 90 degree exhaust pipe bends welded together should do the trick. Look in places that do car exhausts, the bends should’nt cost very much, if anything. That way you’ll have smooth bends and eliminate any restrictions in gas flow. The only thing that might be a problem is the diameter of the pipe, the smallest i could find was 50mm ID, but you might be able to find something smaller, if thats what u need. Good luck

hey Gene and RMC is this what you meant.

it took 5 hours hows that for customisation.

I wanted to thank you both and sorry i write too much.

Hi Justin,

I know u probably dont have the tools but i would also suggest round tube bent through 180 degrees with a pipe bender. It would also be useful if you have a system of sliding pipes so that you could change the length of the exhaut quickly, that way fine tuning will become way easier.

Gene

hey Gene i know know what you mean. the pressure would pile up at the 90 degree bend and slow down the flow ill fix it right away.but other than that dose every thing else look ok?

Hi Justin

From what i’ve read about valveless pulse jets they seem to run off a concept known as “resonant frequency.” This means that the speed of the explosions ie. the amount of detonations per second, has to be close to the frequency at which the jet pipe naturally resonates when you tap it with something. Looking at you engine i see that you have two 90 degree bends. Unfortunately not only will this impede exaust gas flow it probably also means that the engine will not run, and if at all only for a very short time – at which point the fuel mixture will become too rich and combustion becomes impossible. Also i agree with RMC, that gas you are using is not ideal. It is probably stored at a lower pressure that would be found in say a BBQ cylinder – and if that is for lighters then it will be propane, which is not as volatile as LPG (in my experience). Anyway hope i helped in someway.

Gene

The spark plug is just a glass fuse like these with a single wire passing through. This wire is connected to the live terminal of a small HV supply, while the metal case of the jet is connected to ground.

When switched on the spark jumps from the tip of the wire to the jet casing.

one other thing….

can rmc please give instructions on how to make your spark plug

I think the site Justin is refering to is this one.

http://www.vhp.co.uk/turbine/pulsejet.shtml

You are welcome to post links, but you must just paste the address (without any html code) as links are not automatically parsed (made clickable) because this would make us prime target for spammers.

justin can you please copy the name of the website with the plans of your engine and paste them in a comment so i could get to them? i couldn’t find it your way!

thanx

In this copper pipe example the holes are drilled so that the pipes are a tight fit, and the gas pipe was soldered to make a better seal.

This is definatley not a jet you should make for propulsion as the materials used make it quite dangerous.

The best material is usualy steel as it is tough, and the parts can be welded together. You could also find many parts that can be screwed and bolted together, or you could make them youself if you have acces to bench machinery.

I must say though that a 13 year old kid with two homemade jet engines strapped to his bike sounds like bad idea. :O Whatever you decide to do, be careful! 🙂

How would I be able to make the little holes for the fuel and spark plug, and what to seal them with so they don’t blow out. I’m going to make 2 for my bike :). And what would be the best material for making the jet?

Thanks, Max

P.S. I’m 13! HA! Younger than ALL of you :D.

4 – Business End

Hey Guys,

Just thought it would be a good idea to let you know how i’m getting along with my engine (everyone else thinks i’m crazy). I have done one successful test run to date on LPG an the engine has awesome power, the little bugger spools up like you would’nt believe and that was only at 60psi gas pressure (half throttle). The pictures I have included are the most recent of the engine and show my progress after aprox. 2 months. BTW nice job on you engine Justin just wondering if you have sorted out the problems you were having? Anyway, thats all from me,

Gene.

hey ian the pulse jet design i used was from another site valveless pulse jet this is on images type it in and look for a little orange black picture and click on it then you cansee the engine video down the bottom and the plans at the top. p.s to send a picture just click on add image when you make a comment and use brows to find the picture. i dont own this site so it would be better to ask the professional RMC

Justin, i was looking and i seen your comment “I built another pulse jet but like your only runs for a couple of seconds, I tryed to send a pictuer but the site wont let me so I’ll have to describe it.

IT has no curve and is a simle jet design.”

And i wondered if you could let me know how to make it or where the plans are.

thanx

Iain, Aitken91@msn.com

I’m not sure how much not curving the exauhsts will make to how well it fires, but I excpect it will only slightly alter the overall tuning.

Your longest exauhst looks like it may be too thin. It might work better if it tapered outwards like a cone shape. This is also helpful for starting the jet as you can blow air in this end (not with your mouth!) to kickstart the pulses.

this is my jet

No by this I mean it is a pulse jet like a lockwood hiller but just dose not curve forwards for added thrust.

I was thinking of making the inlet bigger or repositioning the fuel inlet.

i’ll send a pictuer when I get home from school.

Thanks for helping me with this.

I build the jet to get a better understanding of jet engine basics for example insted of narrowing down the combustion chameber and making the duct two tail plpe smaller i’ll just make the two the same size and use a normal not narrowed chameber.

Hi Justin,

I have just Added an image upload function to the comment forms. You can now include images in your posts.

When you say your jet has no curve, does this mean that it you are using a valve type system?

I have a question to ask. I built another pulse jet but like your only runs for a couple of seconds, I tryed to send a pictuer but the site wont let me so I’ll have to describe it.

IT has no curve and is a simle jet design.

please get back to me with some info on how to start it properly and or fix it.

Hey Justin,

I’m building a gas turbine aswell. Are u using a car turbo or are you building it from scratch?

For mine i’m going to use the turbo off a WRX the rest i will fabricate myself. I’m thinking of starting the engine on LPG then when it get warm enough switching to Kerosene just curious to know how far along you are with your engine.

hellow again I did find your information usefull but im now into gas turbines,i find them a bit more reliable,easyer to start,and they are to me easyer to buid. the only problem i face is the ball bearing exploding or grinding away from the extreme pressures andd heat. to solve this i have a high pressure oil and coolant set up.

With the picture shown, the jet was difficult to start but it could be made to run for a few seconds until the fuel was disconected or the jet misfired and went out. It has never been allowed to run for more than 10 seconds contiuously.

We replaced the large cone and connecting straight pipe with a cone shaped tube made from a rolled metal sheet cut from a large drinks can.

This improved performance and it would pulse nice and loud with a regular and rapid ‘beat’. Unfortunatley the poorly constructed cone was soon destroyed. It may be better to use something more sturdy such as the metal sheeting available in DIY stores.

None of these parts were screwed in place. Some joints were soldered whilst others were simply crimped in place so that they could be adjusted.

To start the jet engine you must use some kind of air blower. For this example the outlet from a mini hoover from a PC cleaning kit was used.

Im a kid in australia aged 15 and have built a few jet engines and they have worked but I find the pulse hard to build as stupid as it sounds been the easyest to make. I cannot seem to get the dimentions corret when building them. Dose your simple design with the tubing screwed together work?

We have no such specs as this jet was not made for propulsion. It could only be operated for less than 10 seconds, and using butane fuel the thrust produced was far from enough to lift its own mass. It would probably produce more thrust if a better fuel mix such as propane/kerosene were use, but this would likley cause this pulse jet to blow its self apart!

This jet realy is only for proof of principle, as it demonstrates how the exauhst is blasted out before air is sucked back in. Using common copper fitting means that parts can be easily swapped and adjustments can be made.

If you wanted to make one for actual propulsion it would be neccesary to find better tubing materials. The walls of copper fittings are far to thick relative to the diameter of the tubing, which makes it unneccesarily heavy. Some sort of thin steel tubing such as that used in ventlation ducts might be suitable. The joints could also be welded, but you would probably need to make all your own pipes and fittings this way.

What are the specs? In particular, maximum thrust and exhaust velocity. Also, fuel economy.

The longest part in the pictures is about 20cm long and the combusion chamber is about 4cm in diameter.

How big is this jet engine please?