How to Make a Van De Graff Generator

(An Electrostatic Generator)

There are a number of devices that utilise contact electrification. A popular device is the Van De Graff Generator as it is very simple to construct. This device will produce very high voltage electricity at very low current. This means that they can be safe to touch, although it may make your hair stand on end!

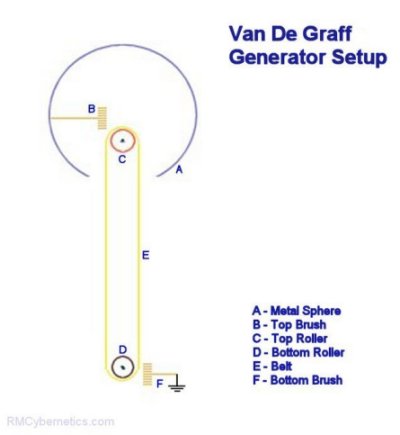

It works by using two rollers and a belt made from dissimilar materials. As the belt rotates, charge separation will continually occur at the point where the belt moves away from each roller. If a metal brush is placed near to these points then the charge can be collected or deposited. The choice of belt and roller materials will determine the polarity of the voltage produced.

A very simple mini Van De Graff Generator can be made from household parts. It wont make your hair stand on end, but it could produce as much as 20,000 Volts. The following parts (or equivalent) can be used for this project.

A very simple mini Van De Graff Generator can be made from household parts. It wont make your hair stand on end, but it could produce as much as 20,000 Volts. The following parts (or equivalent) can be used for this project.

Large rubber band

Large glass fuse

Small metal rod, or a nail

Plastic pipe (~4cm diameter)

Insulation tape

Small motor & batteries

Empty drinks can

Wire

First of all a piece of PVC pipe or an equivalent insulating support is cut to size. To this the rollers are attached at each end. The top roller should just spin freely on its axle. The bottom roller should be parallel to the top one and raised up from the base of the support so that is can spin freely and be driven by a motor.

The belt should not be too tight that it creates excess friction as this would be noisy and inefficient. It is common to create a belt driven pulley to link the motor to your bottom roller as this provides a speed reduction and torque increase from the motor. A motor speed controller would also help so that the speed can be adjusted for optimum results.

The wire brushes should be place near to but not touching the roller or belt. It is likely that you will need to experimentally determine the optimum position of the brushes.

The top sphere acts like a capacitor to store energy in the form of displaced charges. Ideally is should be large, round and smooth. Any sharp protrusions on the outside of the sphere will cause corona leakage and prevent a good build up of charge. A single drinks can will work on a small scale and they can even be stacked together for better results.

I am trying to find people who have been able to duplicate Piggott’s experiment circa 1911. See http://scripturalphysics.org/4v4a/ADVPROP.html#PiggottLinks

Piggott used an industrial strength Wimshurst machine but a robust Van de Graaff should work too. It would have to output 500,000 volts at probably 50-100 microamps (probably requires sprayed charge). The output must be monopolar (+)and pulsed at 10-50 Hertz with fast rise times and slower fall times. A spark gap and saturable magnetic switch (easily constructed) and other components could approximate the waveform.

I would be very interested in comments or experiences pertaining to this topic.

The current is just too low. I would take a long time to charge the capacitor.

You can power an electrostatic motor with them.

Is there anything that a VDG can be used to power?

But I thought all that needs to happen for a TC is the electricity from a capacitor jumping the spark gap and moving through the inductor. Why isn’t there enough power to do those things? Doesn’t a TC need a HVDC input?

No, there is not enough power generated by a VDG.

Can a Van De Graff Generator be used to power a tesla coil, so that the TC could be run on a lower current? Would the TC still make plasma?

Yes, having the collector higher from the floor (but not too close to the ceiling!) is best, but you just have to make sure it is practical to build. A long belt might flap around and hit the sides, or its self which would be detrimental to its performance. You’ll have to Google around for more triboelectric charts as I don’t know of any with much more on them. On the other hand, you could experiment with materials yourself and develop your own unique chart.

O I see, thank you for clearing that up for me. So I should determine the belt length in reference to the voltage of the machine? Also where can I find a more advanced triboelectric chart, I am looking for a chart with more materials. I have decided to use silicone rubber for the bottom roller.

The triboelectric series is also useful for choosing your belt. The belt should be made from a material somewhere between the materials of your rollers.

The height is used to isolate the high voltage parts from ground. If it is too low, the high voltage would just leak through the air back to earth. Building this device, like building any device is about finding a compromise between the optimum physics, and what is actually practical.

Yes but the triboelectric page really only is helpful for the roller material. What about belt materials in reference to the roller material?

Also if the wider the belt the faster the charge time, what does the height of a VDG determine, is a longer belt better?

I have checked the triboelectric series page but I have not anything on the belt material to be used.

Also maybe I am a little mixed up, I thought that the sphere was just to act as a capacitor, thus the larger the sphere the more current stored and the more power available. Also if the sphere controls the voltage than what id the purpose of building a 5′ tall vdg, why not build it smaller like 2′.

A lager collector (metal top) allows for higher voltage. The rate of charging is determined by the width of the belt as more width gives a larger contact surface for electrification.

PTFE and latex should be fine. The triboelectric series is what you should check.

Hi, I have a few questions about vdg’s.

First of all I was wondering what constitutes the voltage output of a vdg? Is it related to belt lenght?

I am using a glass tube for a top roller with ball bearings istalled in each end, and was wondering if ptfe (Poly Tetraflouro ethylene)

is good for a bottom roller? Also with these materials for rollers I was thinking about latex rubber for the belt, is this a good idea? What is the best material for the belt?

Thanks alot for the help.

Again, yes if it grips. I can’t tell you how long it will take. The factors affecting performance that I listed are not exhaustive, there’s many more. The same VDG could take 1 second, or maybe not charge enough ever. The positioning of the brushes is also critical and you will only get it right through experimenting with your setup.

Can I use a strip of polyester cloth instead of rubber since it is further below on the triboelectric series? For normal humidity conditions, a belt width of 3/4 inches and a hemispherical dome of a diameter of 10cm and if the belt rotates 2 times completely in a second, what would be the time taken to produce a 1 inch spark???

Yes, if you can get it to grip the rollers effectively.

The time taken to charge and the length of spark depends on a lot of factors.

The bigger the topload (metal sphere) the longer the spark can be.

The width and speed of your belt will alter how fast it can charge up. Wider is better as there is more contacting surface.

The atmospheric humidity can also have an adverse effect. The air needs to be quite dry for good performance.

You don’t need to be barefoot. It will still zap you as charge will soon leak from your body into the air or through your shoes.

Can I use silicone tape instead of rubber?

I feel that since, it is farther away on the triboelectric series, it would produce a better voltage. And how much time would it need for a rubber band based VDG to produce a spark of an inch? Will it be a sufficient earth connection if I touch it barefoot? Will I get an electric shock? Sorry for the hail of questions.

Some dimmers are not suitable for inductive loads like motors. Check the product specifications to see if it is able to do so.

would an ordinary dimmer switch work as an AC motor speed controller?

You need a proper earth connection to a rod in the earth or you can connect a wire to a metal tap in the home.

how do you earth a vdg a stake in the earth or via the moters earth???

A standard capacitor wouldn’t be able to support the very high voltages generated by a VDG. A Type of capacitor known as a Leyden jar could be used.

I have to check, VDG machines always use metal sphears to store the charge. Wouldn’t it be possable to store in a standard capacitor?

hey toby could us please list which lego pieces you used cause using lego sounds like a good idea

I’ve just made a lego VDG which works really well. The bottom roller is plain lego and the top roller is lego with a wrapping of aluminium foil. The brushes are simple slpayed out multi strand copper wire and the top collector is an inverted drink can. The belt is a long rubber band. It seems to work well even with the brushes actually touching the belt.

my comentary is…

this is the brush and aluminium roller

here is my latest progress. thanks again for the advice.

Please read the previous posts regarding the roller materials. Use the Triboelectric series to identify good materials.

Obviusly this list only has a few materials on it so google around to find the positions of other materials in the triboelectric series.

The issue you mention for glass is just due to its relativley high (compared to low density materials like plastic) specific heat capacity. You might get the same condesation effect as you would with any glass or window that has a lower or different temperature to its surroudings.

If your VDG is just in a house then you are unlikley to have any condesation problems. It may only become an issue if you took it out into the cold for a while and then brought it indoors. The cold glass would then cause moisture in the air to condense onto the roller. The same would occur for any metal parts, but the temperature of these will equalize more quickly.

RMC what would be the best +ve material to use?

I was gonna use glass but someone said it was to be avoided due to temperature change and humidity, can you help? p.s This is only for a small generator 12 inches tall.

Enclosing the belt might help if it were completley sealed up, but it would probably not give any significant boost in performance.

easily fixed i will cut a rectangle at the bottom of the sphere and pull up two metal strips and glue in place. thanks for the heads up.

also i will add a glass roller at the top from an old V drink bottle for extra power.

if i was to add a inclosed structure around the belt, would that prevent humidity?

the belt will be made of black durable plastic found in all good hardware stores.

Looking good. If you can mount your top roller and brush inside the sphere you will see better performance.

This is because all the like charges are trying to get as far from eachother as possible. When they are able to move (on a metal object), the charge will distrubute its self around the outermost surface. If the wire from the brush is sticking out of this sphere, charge will be trying to get back away from the sphere as this wire is the outermost conductive point. This will leave your top brush fighting to add more charge to the sphere. If the brush and roller are inside the sphere, the charge will be heading straight to the outer surface of it. The only things sticking out of the metal sphere will be the support and the belt which are both non conductive.

this is my new generator in progress.

dose it look like im on the right track? i put tape around the edges to prevent cornial discharge as you explained befor

Can you put an induction furnace on your page and how to make one please.

p.s i got some materials and im building my generator and justin i did check out your page lol.

thats very interesting i never knew that.

i finaly got 2 inches of spark with my mini vdg which for its size is pretty good.

i would take a photo but it lasts only for 1000th of a second. i used a lightning rod ball thingy.

im making a bigger vdg and used your advise as posted in the previous responces about lakering wood. i also added electric insulation tape.

thank you i will try that.

have you noticed that the spark produced is much like a fly back transformer it starts glowing purple then sprays till a big arc froms

Yes, this interesting effect is called ‘corona discharge’. It used to be known as St. Elmo’s Fire after it was noticed by sailors during thunderstorms.

This drawing shows how the masts of the ship act like sharp points on a charged sphere (earth) causing the surrounding air to be ionized.

I found that glass is one of the best +ve materials, but it’s difficult to go at any speed without breaking it. Nylon is a common choice as you can carve a roller from an old chopping board.

RMC you may very well already know this but through my testing ive found that the generator will produce 2 times as much voltage when the speed is doubled also i found that posistioning of the combs will dramatically change your results.

a good ve- would be electrical tape, teflon and pipe seller tape the good ve + im not so sure.

Just a plastic pipe from your local DIY store is fine. I’ve had no problems using PVC pipes for supporting the top of a VDG.

Anything insulating (usually some sort of plastic) will do the trick. You could even build one from a tower of lego.

please suggest a material for the support column

Wood is not great because it can absorb moisture form the air but if it is well dried and varnished it should be no problem.

The support can be any shape and it does not need to enclose the belt. It just needs to be a good electrical insulator which can be used to support the top sphere and roller assembly.

i was searching on the net and found that pvc is bad for vdgs so would wood be good and dose it have to be in the form of a cylinder. ps could you sugest a easily obtainable material for the support columb

i was thinking of that but i though it may contain carbon

I’ve not tried that material, you’ll just have to test it out. The moisture absobing propoties of it may cause problems if the air humidity is high. I’ve seen projects where people have use strips of bin bags for making large belts.

thank you very much

im making a much bigger one about 130cm tall but need to know if this material would be suitable for a VDG belt i would think so but im not sure.

james if you need help try my web site but youll find better quality information on RMC’s

http://www.justinlaird.piczo.com you might have to search a bit

Nice 1. If you want to add a video clip, upload it to YouTube, then in your message just paste the URL. of your clip. Someone will then embed the video in your message for you.

Now you have a working van de graff generator you can do experiments like franklins bells

this produces about a 1 cm spark which is about 20 000 to 25 000 volts but low current. this was taken when turned off but charge is still held on the sphere the paper seen at the top stands on end and you can feel air rushing towards your hands as well

here is my one

man cheak this out my first van de graff not great but its the first thing that actually works but the glass fuse smashed so i tried plastic.

For the most effective contact electrification to occur between you belt and rollers they should be as far apart as possible in the triboelectric series. If your top and bottom rollers are made from materials from the top and bottom of the triboelectric series, then you belt should be made from a material that is somewhere in between them.

Rubber is a common choice, but it must not be the black rubber you often find used as drive belts as this contains carbon.

Drive belts are often round, but ideally the belt should be flat. With more surface area in contact with the rollers it will perform better.

if i was to make a belt for the generator what would be the best matrial also i might use a vaccum belt from an upright vaccum belt drive. would this matrial be good for the generator?

The materials chosen for the belt and rollers are determined by the position in the Triboelectric Series. Glass is pretty close to the top of the +ve end of the scale, but PVC is near the bottom of the -ve end so this is not a suitable replacement. Maybe the PVC pipe would be good for the bottom roller while using Nylon for the top roller. Alternatively you could wrap a small piece of leather around a piece of PVC pipe.

for the van der graff generator dose the top roller have to be glass or could it be pvc pipe because i no that pvc holds a good static charge i just want to make sure. please get back to me soon.

Show me complete instructions for the generator, please!

Yes, connecting a HV DC source to the lower brush instead of connecting it to earth will boost the performance of the VDG.

could you add a negative potential to the ground brush? would that do anything?

A VDG like this will reach 20kV within a few seconds. If a grounded object (such as a finger) is placed near the metal can, a spark will jump the gap. A rough approximation for voltage vs spark length is 1kV/mm.

This is about as small as it can be made whilst still being able to accumulate enough charge. The contacting surface area of the belt determines the charging rate. The size of the metal can determined the amount of charge that can be stored on its surface.

how long does it take to generate 20kv and will it create a spark and if so how. also whats he smallest it can be made.

Thanks,

Marc

Any metal should work fine.

dose the brash have to be copper and dose the generator have to be encased in a plastic tube

what are the van de geaff important works

The copper brush is simply some standard multistrand wire. Just strip the end and spread out the strands.

how to make a copper brush